This Win of the Week highlights how Augury’s continuous monitoring, with support from Augury’s vibration analyst, helped the onsite team at a well-known American chemicals manufacturer avoid significant damage and repair costs for two waste blowers, as well as a huge loss in throughput.

Industry – Chemicals //

Machine – Waste Blowers //

Fault Type – Structural mechanical looseness and axial unbalance //

The waste blowers collect trimmings from large, specialized paper rolls critical to the manufacturing of protective coveralls, gloves, and house wraps. The company leverages Machine Health for Critical Assets (MH CR) to monitor many of its assets. When Augury detected high vibrations in the two waste blowers, coupling and bearing issues were identified. Repairs were carried out quickly with minimal downtime, preventing damage to the blowers early on.

Detecting Coupling Issue Early On

When Augury’s AI detected a sudden, large step increase in the motor axial vibration of the first waste blower, the vibration analyst immediately downgraded the machine’s health status to Danger and alerted the onsite maintenance team. He recommended inspecting the machine for mechanical or coupling issues and repairing the machine as soon as possible, running it with caution until repaired.

The maintenance team quickly inspected the blower and discovered a coupling hub had slipped on the shaft, causing inadequate spacing between coupling insert flanges. The couplings were rubbing together, which caused the spike in vibration. If left unaddressed, the couplings would have worn down and eventually damaged the fan shaft as well.

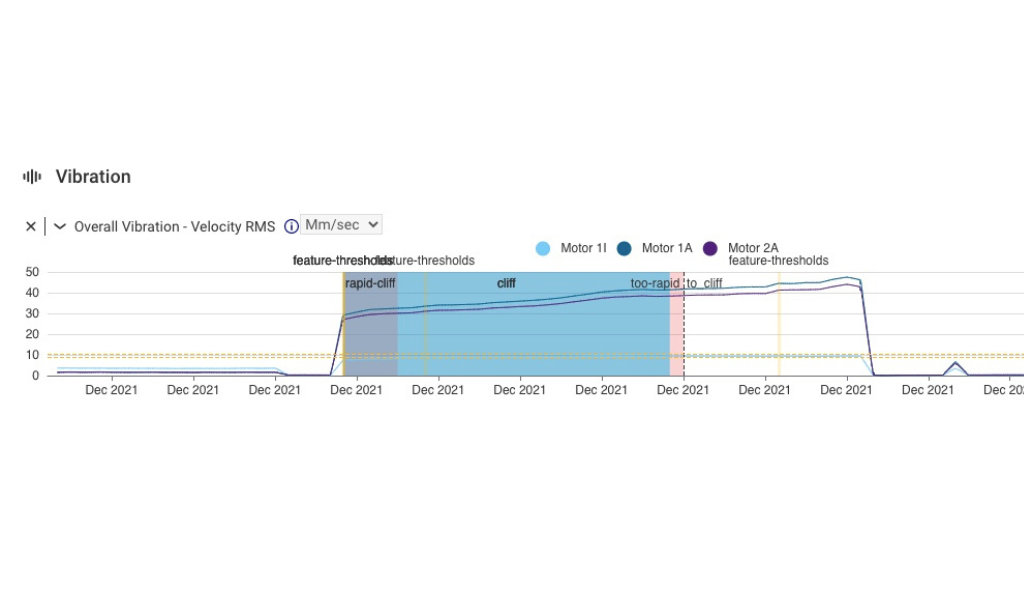

Image 1:

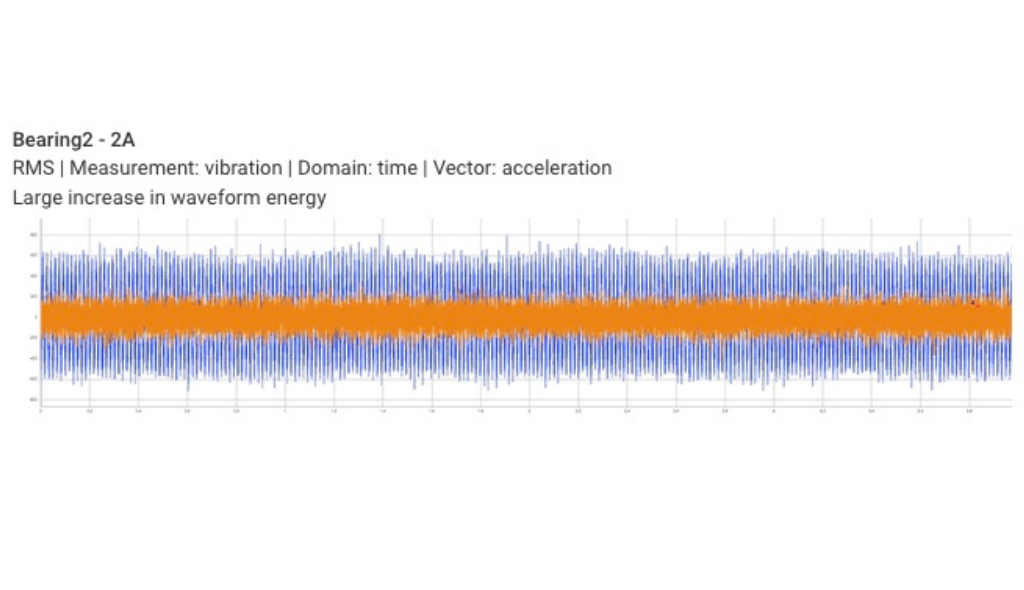

Augury’s algorithms analyze over 840 unique feature sets. This image depicts the velocity RMS, showing a sudden increase and rapid-cliff detection in the blower’s motor velocity trends due to a coupling issue.Image 2:

This image shows the large increase in waveform energy (blue) at the time the fault was detected compared to when the machine was running normally (orange).The onsite team repaired the first blower immediately; the couplings were reset in the correct positions then tightened. Within a day and a half, the machine was fixed and running normally. Vibrations returned to normal, confirming the success of the repair.

Concurrently, a large step increase was also detected in a second waste blower. This time, the vibration analyst suspected bearing failure. Upon inspection, the maintenance team discovered that the blower’s drive end bearing #3 was failing due to a lack of lubrication. The team confirmed an oil leak, bearing failure, and a slipping v-belt. They ordered the replacement parts and will perform a planned repair when the parts arrive.

Preventing Major Damage Saves Over $350,000

Augury’s continuous monitoring enabled the vibration analyst to notice vibrational changes and alert the onsite team to inspect the waste blowers immediately. If the team hadn’t been alerted and the first blower continued to run, the coupling issue would have gone on to damage the shaft and the motor.

Because of early detection and the onsite team’s quick response, the manufacturer avoided considerable damage and repair costs that could have involved considerable unplanned downtime and throughput loss of over $350,000.

To learn more about Augury’s full-stack people-first approach that’s transforming manufacturing, get in touch today.