It’s impossible not to feel inspired by Hannover Messe — the world’s largest industrial technology trade show. With over 250,000 participants and more than 6,500 exhibitors, there’s a dizzying amount of industrial and technological prowess on display, showcasing a wave of innovation and movement in the industrial digitization space.

After the weeklong show, it’s clear to see that digital transformation is going mainstream. It would be safe to say that if an organization visiting Hannover Messe didn’t have a top-down digital transformation strategy before attending, they’ll definitely be crafting one soon after.

Still, despite the breadth of sleek dashboards on display at Hannover Messe, many tech companies haven’t figured out how to break the barriers between the technology sector and the manufacturing industry— to prove value at a large-scale. Businesses today face daunting challenges to their digital transformation strategy when trying to operationalize their IIoT-enabled equipment. Adding more layers of complexity and providing more data isn’t necessarily helpful and lacking the “right” data can inhibit the digital transformation process.

As technology vendors and innovators, we need to alleviate, rather than contribute to the complex challenges and misconceptions associated with digital transformation.

One large manufacturing company spent an entire year trying to develop their own integrated approach to smart maintenance using existing data from their operational systems. They believed this digital integration approach would ultimately help increase productivity, but the project stalled and eventually failed after a year — due to the complexity of collecting, synchronizing, organizing and sanitizing the data. One hurdle they needed to overcome was when the OEMs (original equipment manufacturer) of their process machines refused to release crucial data. They are now working with Augury and have seen the benefits of working with a partner who has already developed a database of mechanical failures.

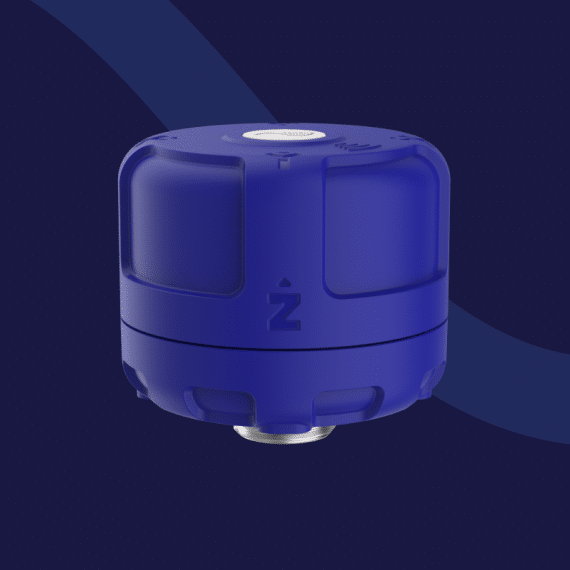

When I was walking the floors of Hannover Messe, it was strikingly clear that machine health is the foundation for digital transformation. Machine health is at the heart of industrial productivity; it unlocks efficiencies while optimizing other parts of the supply chain—and can help create new business models and revenue streams.

To capitalize on its potential, digital transformation needs to become more than a buzzword. It needs to translate into clear solutions that address the complex realities of global manufacturing operations and prove immediate value — starting from the foundation and building from there.

As global manufacturers turn to the tech industry to help them address their most complex challenges, it’s up to industrial tech-innovators to focus and actually solve the day-to-day problems with simple, powerful solutions.

Find out how Augury can help with meet your digital transformation goals.