In this Win-of-the-Week we peel back the curtains to show how Augury’s AI and Machine Learning algorithms diagnosed misalignment and mechanical looseness on a critical oil circulation pump at one of the world’s largest Food & Beverage companies.

Industry – Food & Beverage //

Machine – Oil Circulation Pump //

Fault Type – Misalignment, Mechanical Looseness //

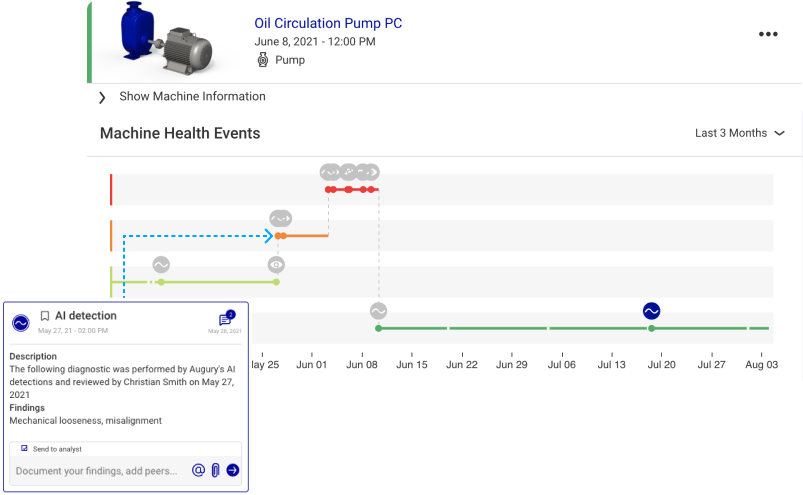

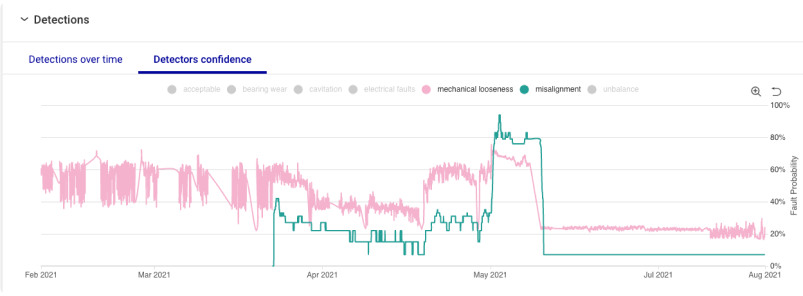

Instead of relying on an army of data scientists to collect and analyze massive amounts of data, Augury’s AI engine is designed to efficiently filter out irrelevant information, elevate anomalous equipment behavior, and assign associated faults based on that behavior. This process occurred on May 27th when Augury’s algorithms flagged mechanical looseness and misalignment developing in a critical oil circulation pump.

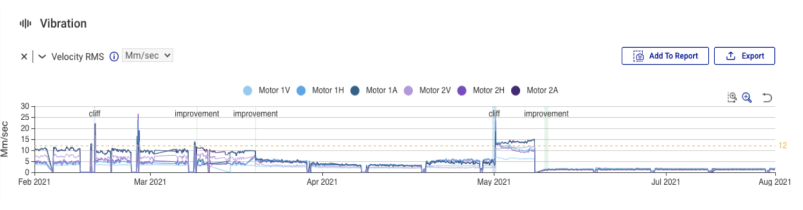

Augury’s algorithms analyze over 840 unique feature sets. Vibration Velocity RMS featured below.

To avoid customers receiving false alarms or inaccurate diagnostics, Augury’s algorithms include detector confidence scores comparing the similarity of the oil circulation pump’s trending behavior with thousands of similar machines Augury’s system has previously diagnosed. Given the high confidence in this diagnosis, the AI detection alert was sent to the site team directly.