The Augury team was in full force at Hannover Messe 2022: gauging the industry response to the recent Seebo acquisition, absorbing the latest techs and trends, and bringing our message of accelerated digital transformation through Production Health to the manufacturing masses. In short: “Everyone’s excited.”

Let’s Future-Proof Industry

After a two-year hiatus, Hannover Messe returned between 30 May and 2 June 2022. Regarded as industry’s premier trade show, it usually attracts up to 6,500 exhibitors and a quarter-million visitors. While the event has not yet returned to its peak, it was still packed with companies clamoring with their techiest of tech solutions. Industry insiders gathered to talk about subjects such as sustainability, industry 4.0, 5G and AI. Robots played chess. There was a rainbow array of branded tote-bags. The surreally graceful flying machines from Festo’s Bionic Learning Network flew overhead. A surprise lurked around every corner…

A lot of people were obviously very happy to be back and interacting. But yes, behind all the bling and ambition, manufacturers also expressed their concerns about the current state of the global economy and people were looking for answers on how to make supply chains more resilient.

Resilience Starts Here

In this setting, the public announcement of Augury’s acquisition of Seebo – whereby the combined power of Machine Health and Process Health will come together to solve the biggest challenges faced by manufacturers today – was greeted with much excitement.

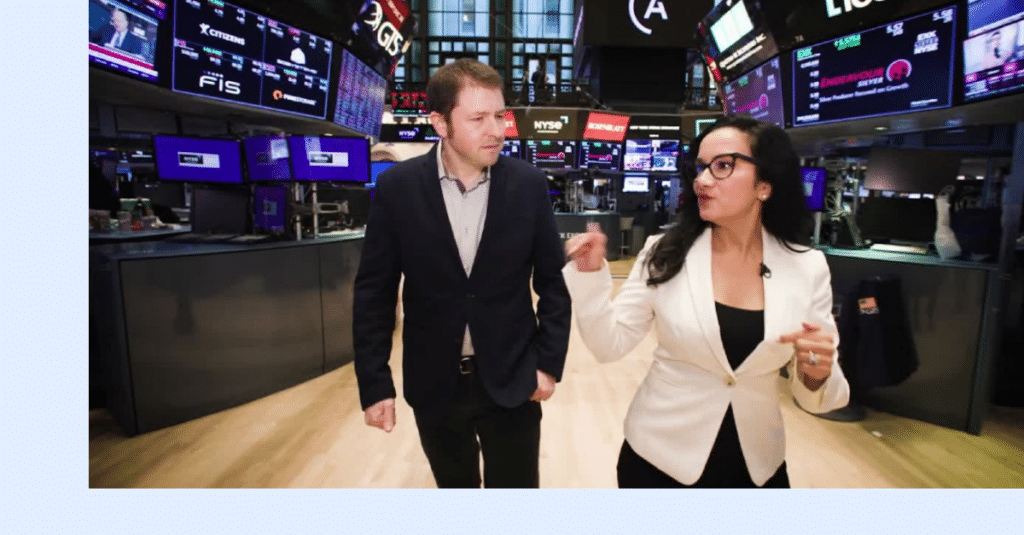

The dual presentation, ‘Production Health: The Future Starts Here’, by Augury’s Director of Market Strategy James Newman and Augury/Seebo’s Solutions Director Lior Akazany, was particularly well-received.

“I’ll never forget it: being mobbed when we left the stage. Okay, ‘mobbed’ might be an exaggeration,” chuckles Lior. “But when we walked off the stage, people came straight for us. They understood what our combined story could mean for them. So naturally, I enjoyed that immediate feedback.”

“People have been talking about digital transformation for a long time. They are now understanding that it’s the only way to stay in the market. And as individual companies, we each offered such a path – backed by fast ROI. Now together, we can accelerate this path.”

The Yellow Brick Road of Production Health

“Everyone here in Hannover understands that managing production lines is a complex business: that the processes need to be optimized across multiple, often conflicting, objectives such as higher yield and throughput versus lower operating costs – while also making sure your machines are capable of running at the same time,” says Lior. “I like to compare it to the Yellow Brick Road. For it to be unblocked, you need all the bricks in place.”

“With our shared clients, it’s a lot easier to explain. They get excited about the Production Health journey,” says Lior. “But for new faces, it takes longer to explain the benefits of bringing Machine Health and Process Health together. But once they get it, they start coming up with use cases that we haven’t even thought of yet – which, in turn, makes us more excited.”

“Seebo’s ability to measurably cut emissions and waste sparked a lot of interest here in Hannover.”

Tapping Into Sustainability

Augury Sales Engineer Matt Bernhard nods knowingly. “A director from a major global CPG manufacturer that’s already a happy Augury client came by the booth and was very intrigued by the merger. He immediately saw the potential of applying AI using both mechanical data and operational process data when it comes to converting production lines. His eyes were sparkling with the possibilities.”

“The existing customers are actually not that surprised by the Seebo acquisition. They see it as a good match,” says Sascha Dainat, the Director of Revenue Enablement at Augury. “And for those who were less familiar with Seebo and seemed interested, I could just send them over to the Seebo booth. We actually had a lot of back-and-forth-ing between our booths.”

“And in general, I think Seebo’s ability to measurably cut emissions and waste sparked a lot of interest here in Hannover where sustainability and ESG are very apparent as overall industry trends,” says Sascha. “It’s no longer a lot of talk.”

“It’s really been a great place to differentiate ourselves from all the traditional technology vendors that are here. We really shine with showing that we can help customers solve problems very quickly and easily at scale.”

Standing Up Above the Crowd

Certainly, Augury’s sales team was in a great position to gain insight into the overall manufacturing landscape. “The value we offer is often quickly understood by those walking by and that says a lot,” says James Newman. “And that’s the real power of the Messe for us: it’s a great place to not only connect with prospects but also potential partners. We had a lot of people coming up to say: hey, let’s bundle our expertise.”

“There are so many different people from so many different industries here,” says Matt. “And many have predictive maintenance, or Machine Health, high on their list of priorities. It’s obviously become one of the key industry 4.0 use cases. So, they are extra intrigued when they realize we offer much more. The conversations have been great! It’s really been a great place to differentiate ourselves from all the traditional technology vendors that are here. We really shine with showing that we can help customers solve problems very quickly and easily at scale.”

Augury’s Head of Sales Development Erik Wall agrees. “There are very few who offer a truly comprehensive approach with both hardware and software implementation. The conversations we had really bolstered the uniqueness of our model.”

“And more importantly for me: it’s improving the day-to-day working lives of those actually applying the solution on the floor. And it’s amazing we are now able to add another layer to that.”

Fine-tuning the Conversation

For Erik, Hannover was also an opportunity to road test ways to explain the new Augury – as fortified by Seebo. “We’re a Machine Health company, which means we have a prescriptive maintenance condition-monitoring solution. Now, we also have a process flow solution. So, it’s tough to really capture both elements in a short pitch. In essence, I think we’re out to help companies optimize the health of their assets. And from there, we need to go down a questioning path to discover what’s important to them so we can be more concrete about how we can help them.”

“I really love my job,” says Ben Huisman, an Account Executive at Augury. “For me as a salesperson I know I’m not just selling a fancy technology. It’s an actual solution that genuinely puts money back into the pockets of the company. And more importantly for me: it’s improving the day-to-day working lives of those actually applying the solution on the floor. It’s amazing we are now able to add another layer to that. And while explaining that perfectly is still a work-in-progress, the response here has still been incredible.”

Augury SDR Borjan Aritonovski certainly had a unique opportunity to polish his pitch. “It’s funny where you can connect here. I was on the bus to our hall, and I started talking to a random guy. It turns out he’s a project manager at one of my targeted accounts and he lives in Germany but was born in Macedonia. I was also born in Macedonia! So suddenly I’m pitching him in my native tongue. He got all excited and now he’s connecting me with all these plant managers across the Balkans and Germany. And that was from just sitting on a bus!”

In short: welcome back Hannover Messe! You never know what’s around the corner…

Watch: ‘Production Health Starts Here‘.

Want to learn more about the impact of our combined solutions: reach out.