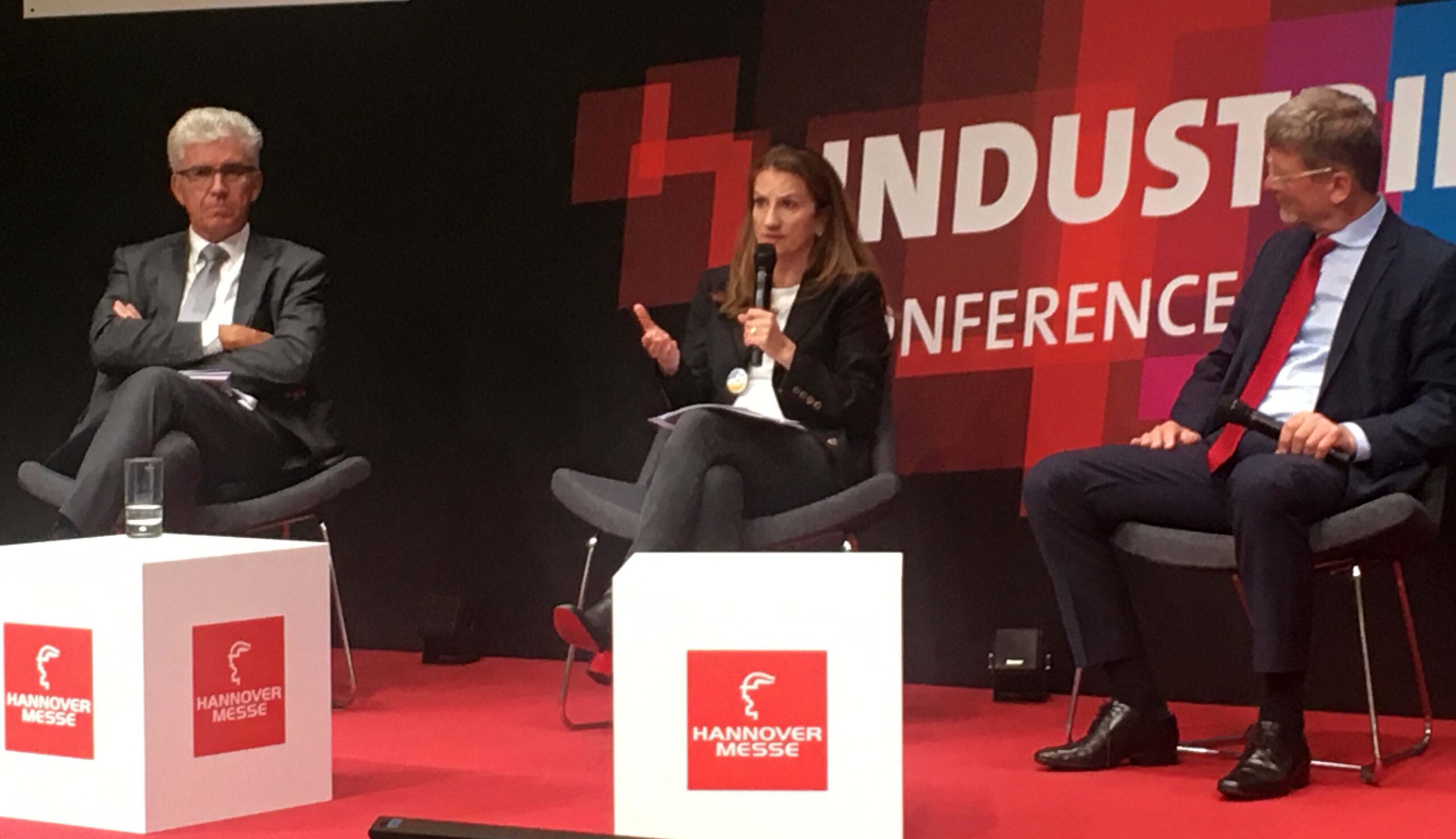

At a panel discussion during Hannover Messe 2022, representatives from academia, business and government gathered for a constructive look at how manufacturing can not only be transformed to increase productivity, but also become a driver of a human-centered, sustainable and resilient society. “Only by bringing the ingenuity of individuals to the forefront can Industry 4.0 technologies fulfill its promise.”

One Goal, Three Perspectives

Bringing together the wildly contrasting worlds of academia, business and policymaking – the triple helix model of innovation – has long been standard for applying AI and data science to human healthcare. Basically, you need to align all three if you want to take on the technical, ethical, social and legal whirlwind involved in bringing a medical innovation to market. And when it works, the pay-offs can be huge – as we recently witnessed with the speedy development of a rainbow of Covid-19 treatments.

The panel discussion ‘Looking Beyond 4.0 – Industry As A Driver Of A Human-Centered, Sustainable And Resilient Society’ at Hannover Messe 2022 showed why the triple helix model should be more commonly deployed in helping accelerate change in the increasingly complex world of manufacturing – especially now when the industry must achieve both production goals and societal ones.

“Industry 5.0 provides a strategic orientation to make companies use Industry 4.0 technologies fully, while maximizing industry’s contribution to a sustainable and prosperous society,” noted the panel’s moderator Liviu Stirbat, the Head of Unit Industry 5.0 at the European Commission.

The View from Academia: First, The Bad News…

As senior research scientist at TNO Innovation for Life, Professor Steven Dhondt is the main coordinator for the EU-funded ‘Beyond 4.0’ research project. He opened the panel by presenting the bad news: wages, employment and productivity all remain too low. “The expected fruits of industry 4.0 are just not there. Yes, there are the 2% of companies that excel in everything, but the 90% who are the followers are really lagging.”

Even companies that are doing well and “speak to our imaginations” such as ASML in the Netherlands or FANUC in Japan are “struggling to make industry 4.0 a great success”, according to Professor Dhondt. “So, industry 5.0 is a new context for companies to think within,” he said. “Companies need to engage their employees to participate in thinking about what’s needed for companies to reach a higher level of productivity.”

The expected fruits of industry 4.0 are just not there.

Meanwhile, according to Professor Dhondt’s research, of those already working in manufacturing jobs related to robotics, AI and big data, only 18% feel they are being listened to by their employers.

So there’s work to be done…

Good Business: Motivating, Capturing and Fostering Workforce Creativity

Doctor Barbara Frei is Executive Vice President of Industrial Automation at Schneider Electric, a leader in digital automation and energy management (and Augury investor and partner). Doctor Frei very much represents the real-world aspects of a company that employs 140,000 people with 300 manufacturing sites worldwide. Happily, she offered good news.

“Involving people very early is key for having a successful implementation of Industry 4.0,” says Doctor Frei. “Sustainability has always been at the core of what we are doing. Already in 2005, we launched our first sustainability program. But it’s not only about the CO2 emissions, it’s very much also how we engage our employees and treat people. It’s really about people-centricity.”

Around 20 years ago, Schneider Electric started deploying short interval management in its manufacturing sites. This involves the site team meeting daily or twice a week to look at KPIs such as quality and output, and discussing methods for improvement – with everyone being encouraged to participate.

The approach worked, but only really took off in 2019 when the process was digitized and became much easier to track. Now 34,000 ideas later, about 45% of these have been implemented. “And that’s so motivating for our employees,” said Doctor Frei. “They can look anytime in one of the PC terminals on the shop floor to see Hey, where is my idea? Has my idea been reviewed or implemented? What was the KPI in the end? How did we perform?’”

We came from a people-centric approach, and then built the industry 4.0 implementation on top of this.

From 2017, Schneider Electric began setting up their Smart Factory Program, which also actively involves those working on the floor and in support functions. They’re the ones who decide what’s best to implement – based on their knowledge of their particular site’s capabilities – in terms of digitalization, automation and making more data-based decisions.

Besides being inspiring for the team, the approach also works to impress customers visiting the site. “The employees themselves present to the customer saying, Look, this is what we have implemented. This is working well… And this is working less well… This gives us a strong credibility in how we’re implementing industry 4.0,” said Doctor Frei. “It shows clients we eat our own food.”

“So, I would say we did it a bit the other way around: we came from a people-centric approach, and then built the industry 4.0 implementation on top of this.”

Policymaking: Supporting the Innovators

Peter Dröll is Director for Research and Innovation at the European Commission. As an EU leader, he represents the political side of the spectrum. He believes fervently in looping in workforce creativity and insight to reinvigorate industry. With manufacturing representing one job out of five, he sees any decline in manufacturing as a direct threat to European cohesion and democracy – citing ‘The Revenge of the Places That Don’t Matter’ as one potential outcome.

“Industry, which in Latin means ‘hard work’, is about going from the individual to the collective, and from the small to the scale. But currently, industry is also not only part of the solution, it is also part of the problem – in terms of emissions and resources. We need to transform,” says Director Dröll. “This is what’s behind 5.0: to bring the ingenuity of the individual, as we heard from Schneider Electric, more to the forefront.”

“So how are we going to do it?” he asked. Basically besides sponsoring research, the EU is putting money where its mouth is, for instance via the ‘ERA industrial technology roadmap for low-carbon technologies in energy-intensive industries’ and more grassroots initiatives such as the first Industry 5.0 Award. “And look out for more Industry 5.0 projects in the future investment package.”

Let’s Get Concrete: Sharing The Success Stories

The second part of the panel discussion addressed what further concrete steps were needed to push through the Industry 5.0 agenda.

Professor Dhondt noted that research should now focus more on the actual workers – “We still need to learn more from them.” He also believes companies should be more actively pushed to invest in themselves and the future.

We need leaders who take risks, who show that it’s possible – that industry can be competitive, clean, and provide a regenerative nature of production.

Doctor Frei named upskilling and leadership. “Upskilling is really key. But we also need leaders who can explain to the team: Why are we doing this? What’s the picture we’re going towards?”

Director Dröll agreed. “We need leaders who take risks, who show that it’s possible – that industry can be competitive, clean, and provide a regenerative nature of production – giving back the human and natural capital. And we need to showcase these success stories of trendsetters over trend followers.”

“As well as success stories about those who upskilled successfully,” added Professor Dhondt.

And to prove the power of stories, the panel ended with Doctor Frei sharing a personal experience. “Together with 300 employees – all of them skilled people – I lost my job once because of a consolidation of factories. We all found a job within the shortest time. I’m happy that this happened, because I would never have the career path that I do right now. So, I believe even if there is a restructuring, there is usually a better opportunity just looking for you.”

Participants of Hannover 2022 can watch the full panel discussion here.

To learn more about how Augury is taking Industry 4.0 to the next level, read ‘The Trillion-Dollar Challenge: Closing The Gap With Production Health’.