Sustainable Operations with Machine Health

As the industry leader in recycled plastic film, Circulus is dedicated to reducing the amount of plastic in landfills and oceans. Uptime is crucial to this mission. Before Augury, their facility teams encountered machine malfunctions and unplanned downtime across their operations. With Machine Health in place, Circulus’ teams have reduced costs, increased uptime, and enhanced plant safety. By combining their people with Augury’s technology they are operating more sustainably and creating a healthier planet.

Machine Health for Safety and Sustainability

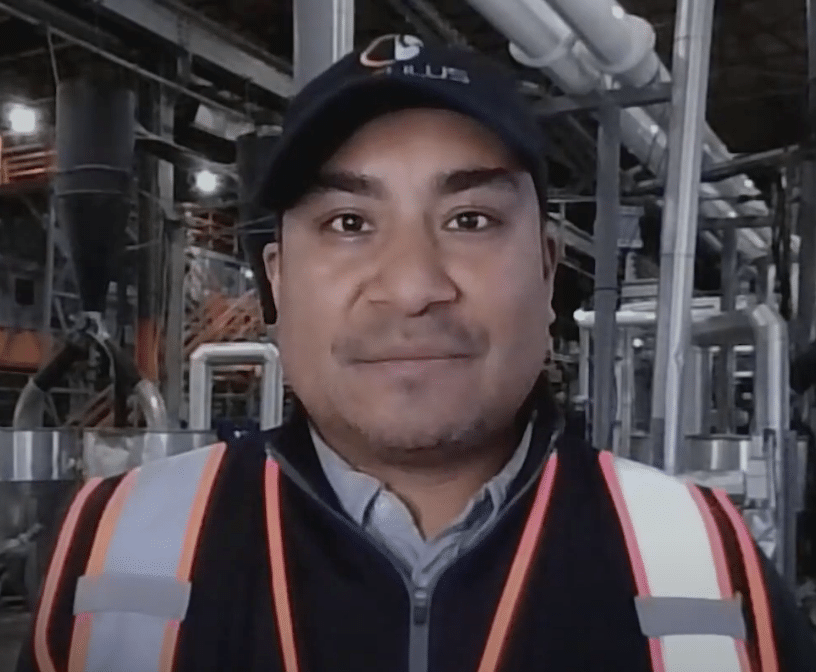

Watch how Circulus is using Machine Health to drive safety and a circular economy