Broader collaboration extends Machine Health to more heavy industry

and hazardous environments

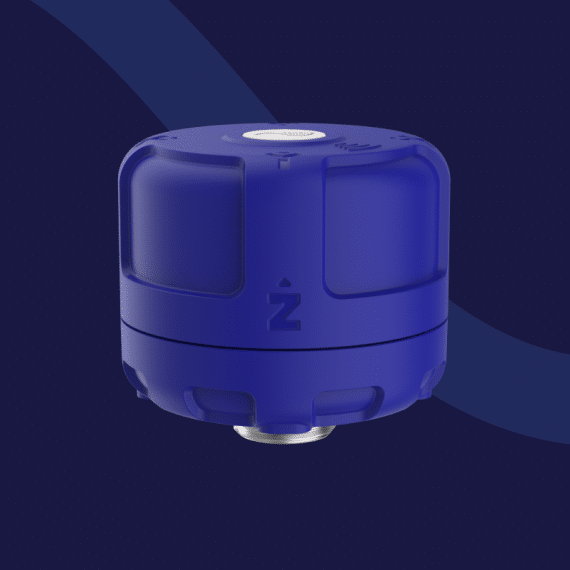

New York – Augury, a leading provider of industrial AI solutions that improve machine health and process health, today announced that the sixth generation of Baker Hughes’ Ranger Pro Wireless Condition Monitoring Sensor and Cordant™ Gateway are now integrated into the Augury Machine Health platform, offering customers greater sensing capability as part of their Machine Health strategy.

The Power of Augury’s AI Meets the Ruggedness of Ranger Pro

The Ranger Pro sensor and Cordant™ Gateway comprise Baker Hughes’ flagship wireless condition monitoring solution, proving essential in oil fields, refineries and other heavy industrial applications where maximizing safety and minimizing downtime are crucial. With over 50,000 sensors deployed globally in heavy industrial and hazardous areas (up to Class 1 Div 1 or ATEX/IECEx Zone 0/1), long-range data transmission capabilities (up to 150 meters line of sight) and a highly efficient IoT network that supports up to 40 sensors per gateway, Baker Hughes’ Ranger Pro sensor and Cordant™ Gateway offer high-precision diagnostics for hazardous areas. Standardizing on Ranger Pro sensor and Cordant™ Gateway for hazardous environments will bring enhanced sensing capabilities directly to customers leveraging the Machine Health offering.

“Heavy industry requires solutions that can handle the toughest environments without compromising on precision,” said Aravind Yarlagadda, senior vice president, Industrial Solutions at Baker Hughes. “Our Ranger Pro sensor delivers unparalleled data and sensing quality, and together with Augury Machine Health’s high-precision diagnostic accuracy, customers can enjoy end-to-end visibility into the health and performance of their balance of plant machines, helping to reduce downtime, increase availability and lower maintenance costs now directly through Augury or as part of our Cordant™ Asset Performance Management offering.”

“Augury’s approach to condition monitoring is unique,” said Assaf Barak, Augury’s VP of Artificial Intelligence and Physics. “Instead of relying on threshold-based triggers to detect failures, we utilize patented state-of-the-art AI models that continuously monitor triaxial vibration, magnetic and temperature data to spot signature patterns that correspond to hundreds of unique faults and failure modes across thousands of asset types. This is the first time we’ve been able to bring this level of diagnostic accuracy to a sensor that was not designed by Augury.”

New Sensing Paradigm

“Our goal was to achieve 99.9% accuracy in Machine Health diagnostics across long distances, with high sensor-to-gateway ratios (to reduce the cost of power infrastructure), and being fully certified for all environments,” said Einat Freidzon, VP of Product at Augury. “Working in partnership, the team was able to integrate both companies’ capabilities to achieve equivalent AI diagnostic accuracy levels in hazardous environments.”

This enhanced collaboration also highlights Augury’s increased focus on extending its IoT infrastructure to incorporate industry-leading third-party technologies through the “Works with Augury” program. This program enables leading IoT and application providers in the Production Health ecosystem to provide faster and higher value to manufacturers around the globe and lays the groundwork for the connected digital infrastructure needed for an AI-driven Production Health future.

To learn more about Augury’s new capabilities in hazardous areas, join us at Augury’s “Beyond the Line” virtual event on June 18, 2024. Register here.

About Augury

A leader in Machine Health and Process Health solutions, Augury uses purpose-built AI technology, trained by industry experts and the world’s largest data library, to help manufacturing and industrial companies eliminate production downtime, improve process efficiency, maximize yield, and reduce waste and emissions. Our global customers achieve 3-10x ROI, often in a matter of months. Together with our customers, we are pioneering Production Health to build a world where the combined work of people and machines makes life better in every way.