With its first annual Spotlight Awards Ceremony, Augury recognizes manufacturing facility teams’ dedication and hard work, going the extra mile with Machine Health. After all, while tech can work to impact people, plants, and the planet, it needs people to make it happen. Thank you to our 30+ site winners, including runner-up Frito-Lay Coventry and our grand winner Fortune Brands New London!

Celebrating Success

The inaugural Spotlight Awards ceremony took place on November 20, 2024. For the first edition, Augury highlighted maintenance and reliability teams with incredible initiative, awarding them the “Beam of Excellence” designation.

Evaluating hundreds of plants, we identified the top 5% of customer sites based on their performance in the following criteria: high response rates, IoT serviceability, number of active users, and quantified wins. In short, these plant teams raised the bar on Machine Health and predictive technology for their companies – and deserve recognition.

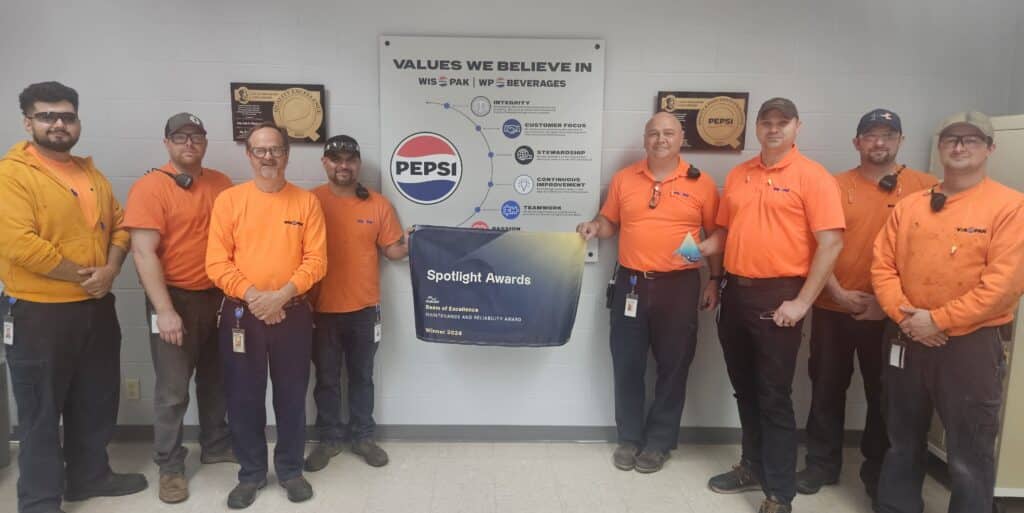

Listed in alphabetical order, the 2024 Spotlight Awards “Beam of Excellence” winners: Amcor / BAZAN Group / Canfor (2 awards) / Colgate-Palmolive (3 Awards) / Dairy Farmers of America / GAF (2 Awards) / Fortune Brands Innovations / Indorama (3 Awards) / ICL Group / Keurig Dr. Pepper / Molson Coors / Nestlé Purina Petcare / PepsiCo (8 Awards) / Reyes Holdings / Roseburg / Toray Industries / Wis-Pak.

It’s About People, Not Just Technology

Hosted by Ed Ballina and Alvaro Cuba, industry veterans and hosts of the popular Manufacturing Meetup podcast, the virtual ceremony opened with special remarks from Augury’s co-founders: CEO Saar Yoskovitz and CPTO Gal Shaul.

“Seeing the work that you guys are doing, the amount of dedication, effort, and creativity that goes into making wood products, food, beverages, toilet paper – and the list goes on and on – has just been amazing and inspiring for us to start a company and see how can we fit in to help you,” says Gal.

“Especially these days, when manufacturing faces so many headwinds, from geopolitical challenges to supply chain issues, the economy, talent shortage, which we all feel daily. And we believe that there is a way out. Right by leveraging technology and modern tools, we can fundamentally transform how manufacturing is being done,” adds Saar.

“This impressive diversity tells a great story about how technology is transferable across sectors and geographies.”

“At the same time, we understand it’s insufficient to put the sensor in the right location. It’s not enough to provide an alert just in time. If there’s no one on the other side to take action to repair the machine, we won’t achieve anything. And that’s why you are such a crucial part of our story.”

It’s In The Diversity – And The Numbers

The winning facilities and teams, covering a broad range of manufacturing verticals, hailed from three continents, eight countries, and 20 U.S. states.

“This impressive diversity tells a great story about how technology is transferable across sectors and geographies,” says Ed.

But there’s another big story: in the numbers. As a group, these top performers achieved:

- 1.3K+ Machine Improvements

- 4,300K+ Hours of Downtime Avoided

- $11.8M+ Maintenance Costs Saved

Incredible Stories Of Cultural Change

However, metrics only tell part of the story. Leading up to the event, each facility helped craft their transformation story – providing additional input about how they’ve transformed the way they work around Machine Health technology.

All of these sites have incredible stories of culture change, digital integrations, new processes, and updated roles and responsibilities. And in the end, two stories stood out and were recognized at the ceremony.

Drumroll Please. The Runner-Up Is… Frito-Lay, Coventry

The runner-up was PepsiCo’s Frito-Lay in Coventry, UK, which was already featured in a BBC feature about how the facility advanced manufacturing through Machine Health. Coventry’s numbers are impressive: a response rate of 94% and avoiding 650K+ costs and 65+ downtime hours.

“The introduction of Augury was a bolt out of the blue. We’ve gone from prehistoric to Star Wars in a couple of weeks,” says Kevin Thomas, Condition Monitoring Specialist at the facility. “It allows me to see the bigger picture and have an accurate story of what is going on. We used to run our equipment to destruction or until the line came down. Now, we can collaborate with the engineering teams to balance production. It feels good not to run about and react to major changes every week.”

“Part of what makes this site’s story so exciting is how they’ve connected the dots not just between Machine Health and cost savings, but also with the tangible impacts of other critical areas like safety, equipment lifespan, and team efficiency.”

And First Place Goes To… Fortune Brands’ New London facility

Like many other winners, the first-place team was initially skeptical due to poor experiences with other systems. However, that did not hold back the Fortune Brands’ New London, North Carolina facility. They fully embraced Augury’s solution, achieving 2.5X ROI in 8 months and 94% Serviceability. The facility is now expanding its Machine Health coverage from 40 to 140 machines.

Part of what makes this site’s story so exciting is how they’ve connected the dots not just between Machine Health and cost savings, but also with the tangible impacts of other critical areas like safety, equipment lifespan, and team efficiency.

“I was a bit apprehensive,” says Ric Wojcik, Senior Manufacturing Engineering Manager. “In my past maintenance life, I was introduced to and tried similar systems that simply did not perform. I could tell that Augury was unique from the other companies and could be a game-changer for us, and I was willing to take the chance. I am so pleased that we did!”

“We’ve seen the difference and look forward to what the future holds.”

Looking To The Future: Upward And Onward

“We are excited,” says Ric. “And it just goes to show that the hard work that went in by these guys – Jesse, Jonathan, Troy, Matt, and Todd – was instrumental in getting all this stuff going on here at the facility. We’ve seen the difference and look forward to what the future holds.”

As Saar put it: “It’s not just solving today’s challenges, but also looking towards tomorrow’s challenges. When we work with you and your peers, we hear these stories of life before Augury: waking up at 2 am, firefighting, heavy, laborious work… Today, you can focus on what really provides more and more impact and what really matters. So, we ask ourselves, how do we take that to the next level? And the answer is by working even closer with you, by listening to your feedback, by having you guide us on our journey.”

Cheers to the winners on a great 2024! Tune in next year for more success!