Augury has its own small army of vibration analysts (VAs). Their main aim is to warn manufacturers of potential breakdowns. But they are also working to remove humans out of this diagnosis process. “At one point, I see the VA taking on a more evangelizing role,” says Christian Smith, Augury’s Manager of Reliability Operations.

With the Augury solution, the goal is to enable people to rely on the machines that matter. Machine learning and automation are crucial to achieving this. Augury’s machine learning algorithms sift through millions of hours of machine data, generating detections of anomalous activity and suspected faults. Vibration analysts then review these detections to tell the client what is wrong, how to fix it and the timeframe before this critical asset actually breaks down.

“In a way, our ultimate job is to make ourselves obsolete. By looping in our discoveries over time, the algorithm will eventually become so accurate, it won’t need the human element,” says Christian Smith.

The Crazy Train to Reliability

Christian is Augury’s Manager of Reliability Operations. As such, he leads a team of over a dozen vibration analysts. “But our Reliability Success Managers are also all certified as vibration analysts. Augury has really invested a lot in reliability expertise and knowledge.”

His relationship with Augury began as a customer. “I was running the reliability program at a manufacturing company and went looking for an industry 4.0 solution. After going over the options, I ended up going with Augury. I was impressed by them, their platform and their culture. I decided I wanted to be part of it.”

“Staying at the same facility pumping out the same products lost its appeal. With Augury, I’m exposed to all sorts of products and industries. So, even though there was more uncertainty with a startup like Augury, I decided to take this crazy train to wherever it’s going,” chuckles Christian. “And I thought, in my field, I’m sure I can find another job.”

“We make machines and production lines more reliable.”

So… What Do You Do Exactly?

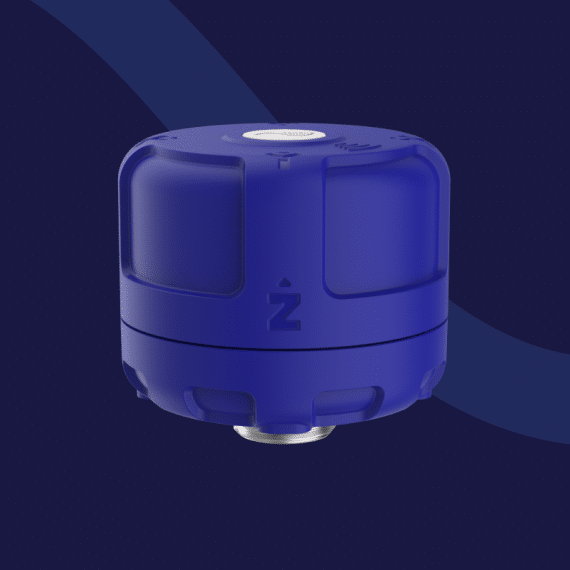

“I actually get asked a lot about my job. People see my business card and ask ‘What’s that about?’ My drawn-out answer is: Vibration analysts at Augury capture data through IoT devices from machines primarily in manufacturing settings. And we analyze the machine’s vibrations to predict fault conditions or components that are going to fail. In that way, we can enable the teams on-site to make repairs proactively and avoid production interruptions.

But if I’m in a rush to pick up my kids, I say: We make machines and production lines more reliable.”

The job is very much more than saying a ball bearing is going to fail in a machine on line 7, according to Christian. “We want to uncover root causes: where the defects are entering their processes. This could be at a machine level but it could be operational – how a factory runs or maintains their machines. Maybe they need to change maintenance practices such as performing laser alignment or utilizing ultrasound for lubrication. Or it could be they store their spare parts incorrectly and that introduces a defect before it’s even installed in the machine. Or it can go all the way back to the beginning: how that machine was designed or engineered. But the goal is to find the root cause, so then we won’t have to call out so many bearing issues.”

The Little Wins

“One thing that really got me excited when I got my original vibration analysis training was how they gave you a peek into other condition-monitoring technologies and the wider realm of reliability-centered maintenance – of which condition monitoring is just one part of. I just wanted to learn more and more,” recalls Christian.

“I realized we did not have to constantly fight fires anymore. We could start looking months and years into the future.”

“It just became my passion: how reliability works to improve the safety and production output of your plant.”

Hands On / Hands Off

Christian originally began as a factory electrician – the ultimate hands-on job. And as he found his reliability path, his job only became more hands-off. “Of course, it was a big transition. Before when working at a factory, the data would tell me something and I’d go out and investigate the problem and often be involved in the repairs,” says Christian.

“It just became my passion: how reliability works to improve the safety and production output of your plant.”

And now that his job is 100% remote, he relies on the customer to take action. “At the factory I was monitoring a hundred machines, and I would run into an issue once a month or whatever and then fix it. At Augury, we’re monitoring tens of thousands of machines. We identify a problem with a critical machine somewhere in the world several times an hour, which we then pass through to our clients,” says Christian. “We see ourselves as partners to the real heroes: those on-site who keep their operations running so our store shelves stay filled.”

“It’s very gratifying to win over people to something I believe so passionately about.”

Going For the Big Wins

“When a problem is fixed, it’s still a win. But the fun thing about Augury is we’re looking at so many machines you get these wins constantly. So now the rush comes from winning over sceptical customers and influencing positive change.”

And there’s two types of customers, according to Christian. “There’s the customer who doesn’t understand the value – who maybe had our relationship dictated by corporate. You just win them over as they see their operation’s numbers improve. Suddenly they’re asking for more information and training, and getting more involved. So that’s great.”

Then there’s the other type of customer who already believes in reliability-centered maintenance. “They have their own vibration analysis programs at their sites and have their own route-based equipment – and maybe they’re sceptical about Augury’s equipment,” says Christian.

“But soon they realize they no longer have to run around in often uncomfortable conditions to collect data that only covers one point in time. We’re covering it 24-7 and collecting additional types of data, like magnetic and temperature” says Christian. “It’s very gratifying to win over people to something I believe so passionately about.”

Going For the Ultimate Win

But meanwhile, Augury is working to automate what a vibration analyst does – that the algorithm will be able to see for itself not just that something has changed, but exactly why and the severity of the issue.

“Yes, the idea is that the algorithm will pick up the symptoms and what they mean and then be able to share with the client what they need to do to fix it. We’ve already made great advances in these areas. And eventually the human experts will be taken over by artificial intelligence,” says Christian.

“But our customers will still always have questions and want some human consultation. Our job will become more about evangelizing: sharing the passion.”

Read the rest of the ‘Life of a Vibration Analyst’ series:

‘Bringing The Factory Home: A Day In The Life Of A Vibration Analyst’

‘A Trade Transformed: 20 Years Of Vibration Analysis’

‘A Fitbit For Machines: With Vibration Analysis, The Goal Is To Extend Life’

Or learn more about Augury’s machine health and reliability solutions: reach out!