Manufacturers know critical assets are vital for continuing operations, but what exactly is asset criticality, how do you differentiate critical from non-critical assets, and how can you use asset criticality scores to drive value?

This article was edited on October 10th, 2023.

How To Identify A Critical Asset

Whenever you put a budget together, there are always those “fixed” expenses that will never go away. For a household budget, mortgage payments, real estate taxes, insurance premiums, and some utilities — though largely variable — would fall within that category. A daily latte from your favorite coffee shop, on the other hand, is more of a discretionary expense that you could do without. Tomorrow, you may decide that it’s more prudent to earmark that money for an actual necessity.

That’s pretty much how to identify critical assets in manufacturing.

Asset criticality refers to how important any asset is to keep business up and running. Whether that means that an asset affects the production line, determines inventory, or represents a large-scale safety hazard should machine health decline, critical equipment analysis provides insights into what’s fixed, variable, and discretionary within operations. You can recognize if a certain piece of equipment is worth the expense — or nothing more than a “nice-to-have.”

Asset criticality refers to how important any asset is to keep business up and running.

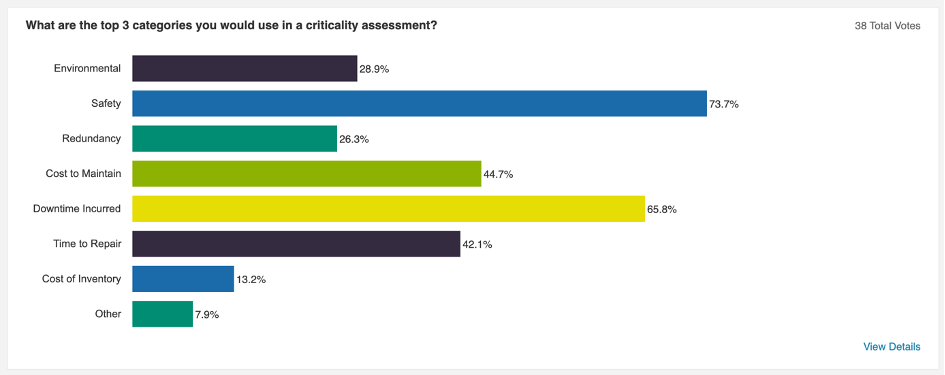

Critical equipment analysis would, for example, keep you from sinking additional money into machine health sensors on something that won’t give you value long-term. Perhaps after conducting a criticality assessment, you find a redundancy, and something once seen as a critical asset would fall into that discretionary category. The first step in uncovering those redundancies is to analyze each asset and assign it an asset criticality score.

Calculating Asset Criticality Scores

Asset criticality scores ensure that each asset you use is critical to business, and Augury can help with the process. We start with the big picture. Our team looks at each piece of equipment on the production floor in need of monitoring and then applies our equipment criticality assessment criteria to determine its overall value.

For mission-critical assets that directly support safety, compliance, cost control, or operational throughput, Augury installs our full machine health suite of monitoring and analytics tools to drive the most value.

Learn More About Augury’s Machine Health Monitoring Tools.

For medium-critical assets, we can also provide lower-cost support with Machine Health for Supporting Equipment. This autonomous and predictive monitoring enables full coverage — though there can be some overlap with this functionality in monitoring high-criticality assets. Machine health for supportive equipment monitoring is more probability-based. What you use it for will largely depend on in-house tech and knowledge base to monitor that data.

Learn More About Machine Health For Supporting Equipment.

Options For Non-Critical Assets

And when it comes to non-critical assets that are only tangentially related to value-driving objectives (a fire pump, for instance), we can determine whether monitoring such equipment still has the potential to drive some value for the overall production line. If so, we offer lower-level monitoring tools like our handheld vibration-monitoring device.

Unplanned or extended downtime can cost manufacturers millions, if not billions, of dollars. Conducting critical equipment analysis and implementing machine health monitoring tools accordingly can help prevent it.

If you’d like to learn more about our services, watch Augury’s Solutions Architect Brian Richmond discuss the business case for performing a criticality assessment and gain valuable information on how to create your own matrix in our on-demand webinar.

How much can Augury save you? Crunch the numbers with our value calculator and discover how much time and money you can save with our proven approach to machine health.