This Win of the Week features a well-known pet food manufacturer, which experienced an important win with Augury. The manufacturer relies on Augury and its vibration analysts to monitor several critical assets, including a belt-driven positive displacement blower.

Industry – Pet Food //

Machine – Blower //

Fault Type – Electrical Fault/Other //

What makes this win unique is that the cause of the issue was discovered through operational insights from mechanical data. The root cause of the blower’s erratic behavior was recognized through a collective, collaborative effort involving the vibration analyst’s observation and the onsite team’s insights on process data.

Sporadic increases in the speed of blower’s VFD

Investigating a too rapid to cliff detection (a very rapid increase), Augury’s vibration analyst noticed unusual patterns in the running speed of the blower’s variable frequency drive (VFD) control. He changed the machine’s health status to Alarm, then checked with the onsite team if the speed change was intentional. The onsite team quickly replied that there had been no recent parameter changes to the VFD and that the equipment appeared to be behaving as it had been in recent months.

Knowing that it is uncommon for VFDs to display such erratic patterns, the vibration analyst thought this could mean something was wrong with the VFD or the logic controlling the VFD. He recommended that the onsite team inspect it, also asking if the automated programming depended on process conditions.

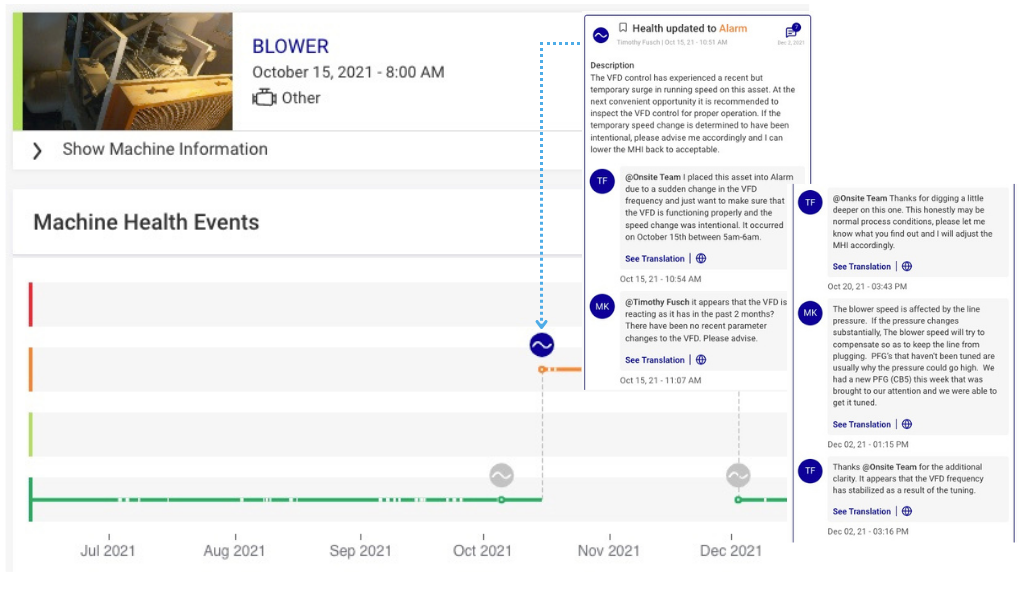

Image 1:

Machine Health status and alerts and tracked, logged, and visible to the Augury vibration analyst and onsite team in the Augury platform as issues are detected and addressed.

Need to tune the pressure control device

After further investigation and consultation with the controls team, the onsite team advised the vibration analyst that the VFD is programmed to adjust based on system line pressures, enabling the fan to prevent plugging from occurring along the production line.

The onsite team discovered that a new pressure control device had recently been installed but not yet calibrated and was therefore not reading the pressures correctly. This led to elevated pressures, causing the speed of the VFD to increase and decrease sporadically, which also resulted in higher oscillating vibration amplitudes.

The onsite team then calibrated the pressure control device to reflect accurate readings. After calibration, the running speed of the VFD stabilized and the blower began running more smoothly. The P2P vibration amplitudes stabilized to around 12g’s as compared to 25g’s, and the machine’s health status was updated to Acceptable.

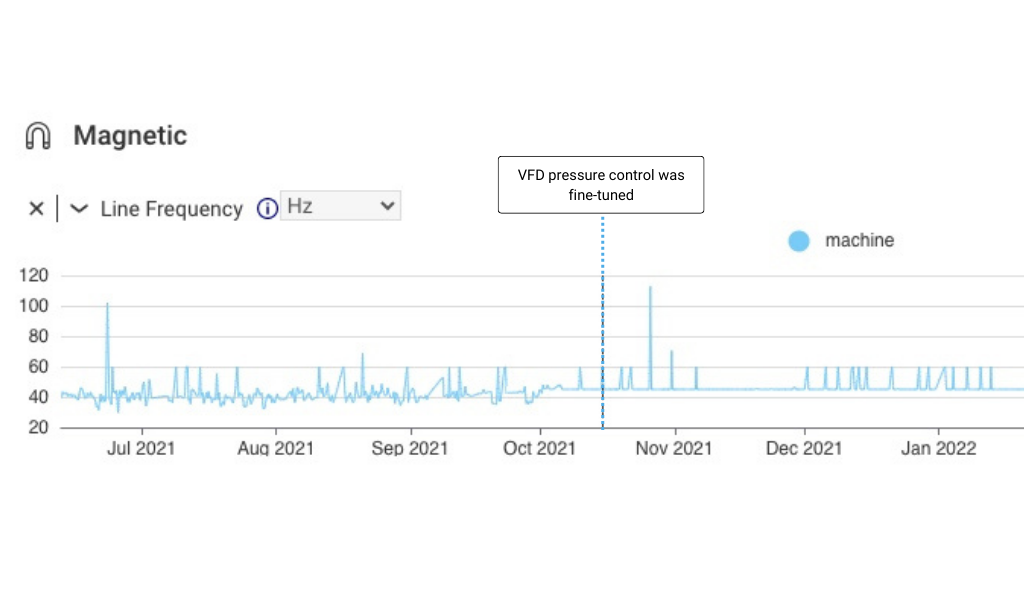

Image 2:

Augury’s algorithms analyze over 840 unique feature sets. This image depicts the line frequency for the blower. It shows the high level of variability before the VFD pressure control device was calibrated, then a clear improvement afterwards.

While there was not an immediate risk of machine failure due to this issue, the adjustment to the pressure control device led to smoother operations and likely reduced unnecessary wear of components in the longer term. By working with the onsite team to understand process data in connection with machine vibration data, Augury took a proactive role in helping this manufacturer improve its running processes.

To learn more about Augury’s full-stack people-first approach that’s transforming manufacturing, get in touch today.