Maintenance and reliability teams, no matter how skilled, cannot be present everywhere and at all times, especially if the team is strapped for resources. That’s exactly why this leading American pet food manufacturer relies on Augury’s solution and vibration analyst team to monitor the health of its critical assets round-the-clock.

Industry – Pet Food //

Machine – Extruder //

Fault Type – Looseness, Misalignment //

This Win of the Week showcases how Augury’s AI detected minute changes in the vibrations of an extremely critical asset—an extruder—and helped the manufacturer prioritize the repair, preventing downtime and high replacement costs.

Making this win even more impactful is how the potential issue was detected, with only limited sensors installed on the asset. Ideally, Augury installs sensors on each of an asset’s bearings to monitor vibrations throughout. However, sometimes a site’s environment or equipment configuration constraints limit sensor installation.

For this particular extruder, sensors are installed on the motor and only one side of the gearbox. But because of Augury’s advanced AI analytics, along with the vibration analyst’s clear understanding of the onsite team’s concerns and priorities, a minor shift was identified as an indicator of potential danger and flagged early on.

A close eye on minute details

Prompted by an AI detection, the vibration analyst noticed the trend in increasing vibrations on the extruder’s motor. He alerted the onsite team, asking them to check both the motor and the coupling for mechanical looseness. A few days later, the vibration analyst downgraded the machine’s health to Danger and again notified the team as the vibration readings continued growing quickly, even though they were still well within the normal range.

The data showed a significant percentage change in the vibration levels compared to previous months, which then doubled over a six-hour period. Typically, this type of change would not have been concerning because of the low vibration levels. However, because of the asset’s criticality, the onsite team had requested that Augury alert them as early as possible to the slightest change. The vibration analyst knew there was no backup for this asset and that any failure would compromise the manufacturer’s operations.

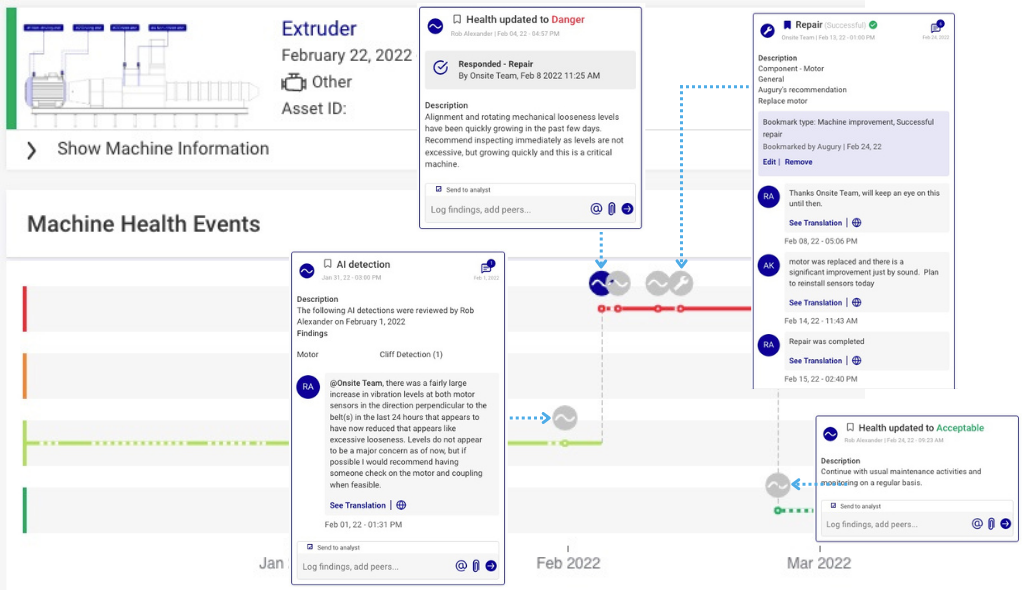

Image 1:

Machine Health status and alerts are tracked, logged, and visible to the Augury vibration analyst and onsite team in the Augury platform as issues are detected and addressed.

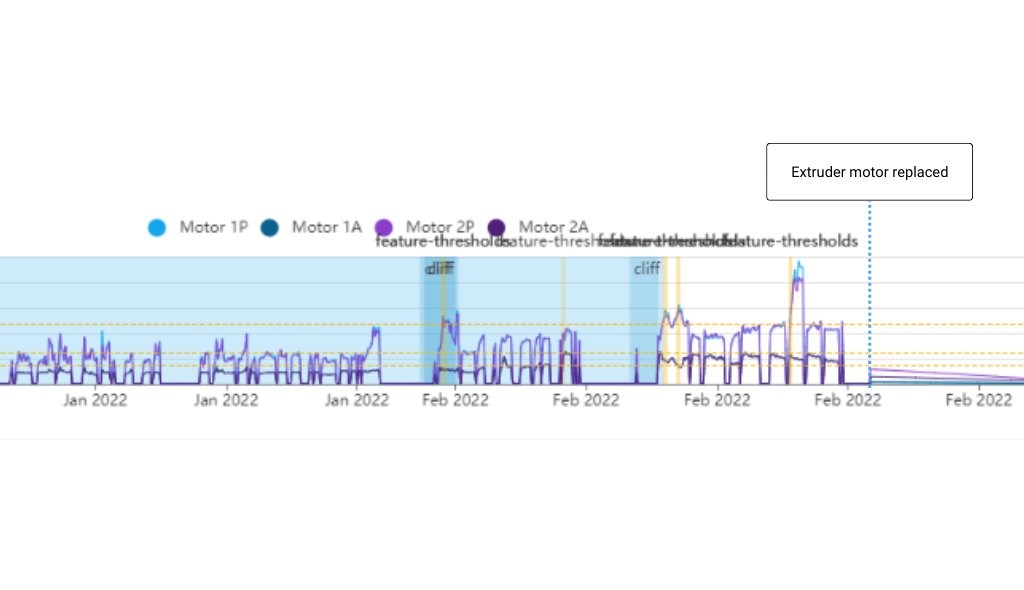

Image 2:

Augury’s algorithms analyze over 840 unique feature sets. This image depicts the velocity RMS and shows multiple rapid increases in the motor velocity trends indicating mechanical looseness, along with the greatly reduced levels after the repair.

Early detection avoids catastrophic failure

Understanding the manufacturer’s challenges, Augury’s early notification and ongoing communications helped the resource-strapped but highly engaged team avoid catastrophic failure, giving them time to stock replacement parts, ensure available manpower in anticipation of replacing the motor, and trigger a work order.

Nine days after the machine was placed in Danger, the motor was replaced. Post-repair, vibration levels improved tremendously across the entire asset, confirming the detection and the success of the repair—also resulting in the lowest operational levels to date on both the motor and the gearbox. The timely repair helped the manufacturer avoid over $100,000 in replacement costs and prevented 8 hours of downtime.

To learn more about Augury’s full-stack people-first approach that’s transforming manufacturing, get in touch today.