Augury stars as a case study in an article on Forbes: ‘How PepsiCo Avoids Pilot Purgatory with Innovation Partnerships’. So, what are the five lessons for success? Read all about it.

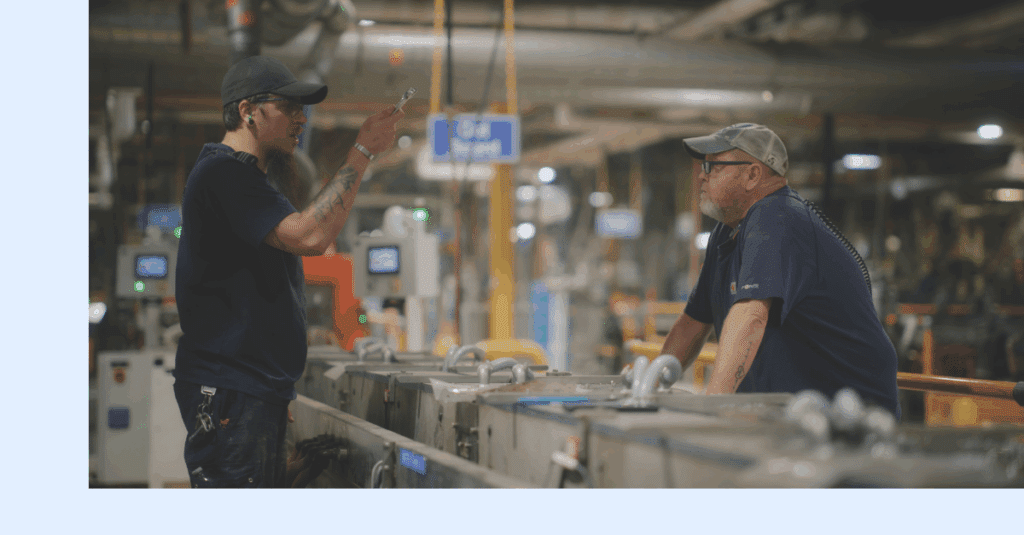

Thanks to its PepsiCo Labs division, PepsiCo has successfully avoided the much-maligned “pilot purgatory” in digital transformation projects. A recent article, ‘How PepsiCo Avoids Pilot Purgatory with Innovation Partnerships,’ outlines five key lessons from PepsiCo Labs’ approach, focusing on its partnership with Augury to reduce unplanned machine downtime in Frito-Lay manufacturing plants.

Escape Velocity: Avoiding Pilot Purgatory

Launched in 2018, PepsiCo Labs has completed over 100 pilots, fostering strategic partnerships with startups to solve core business challenges. By following the lessons PepsiCo learned along the way, companies can improve their success rate in bringing pilot projects from idea to implementation efficiently, avoiding the common pitfall of pilot purgatory, which affects 75-85% of digital projects, according to McKinsey & Company.

PepsiCo’s Lessons Learned:

- Be Focused: PepsiCo Labs defines the problem and success criteria before starting a pilot. In Augury’s case, the goal was to reduce costly unplanned machine downtime in manufacturing plants.

- Pick the Right Partner: PepsiCo Labs sources potential partners globally, screening hundreds of companies before selecting the best fit. Augury was chosen for its AI-driven Machine Health Solution, which predicts and prevents machine failures.

- Clearly Define Stakeholders: PepsiCo Labs provides crucial support and mentoring to pilot partners by connecting them to expertise within PepsiCo. Augury CEO/Co-Founder Saar Yoskovitz notes in the article: “PepsiCo Labs supported Augury by giving us access to manufacturing and technology leaders that helped us navigate how to work best with PepsiCo. It was a perfect match of complementary expertise to help us be successful.”

- Start Smart, But Have Scalability in Mind: The pilot with Augury began in four Frito-Lay factories, allowing for a manageable scope while considering future scalability. Augury’s solution was designed to be easily expandable without significant additional staffing.

- Create a Review Period and Be Ready to Pivot: PepsiCo Labs conducts formal reviews of pilot projects, comparing results from different partners. After one year, Augury’s solution significantly reduced unexpected breakdowns and increased productivity. The article also emphasizes the importance of being willing to end unsuccessful pilots and learn from failures.

Onward and Upward

“Today, Augury’s Machine Health has been rolled out to 36 Frito-Lay sites in the U.S. and Canada and two more in the U.K. To date, Augury has helped mitigate a whopping 900 unplanned downtime events, effectively dodging an estimated 4,500 hours of unplanned downtime.”

Read the full article ‘How PepsiCo Avoids Pilot Purgatory with Innovation Partnerships’.