When it comes to servicing niche machinery, it can be especially important to address issues at the first signs of a fault in order to avoid unnecessary downtime that can impact operations and lead to revenue loss.

Industry – Pet Food //

Machine – Hammer Mill //

Fault Type – Motor Fault (Rotor Bar) //

This Win of the Week shows how Augury’s AI monitoring provided early detection of a motor fault on a leading pet food manufacturer’s critical piece of machinery. This insight enabled the customer to order needed replacement parts — which required several weeks lead time — and repair their machine before a costly catastrophic failure occurred.

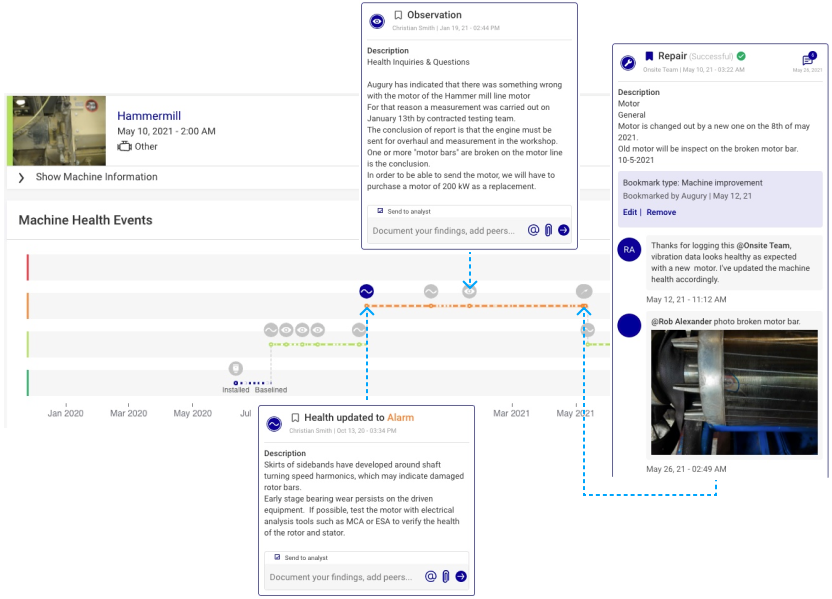

Image 1:

Machine Health status and alerts are tracked, logged, and visible to the Augury vibration analyst and on-site teams in the Augury platform as issues are detected and addressed.

A hammer mill is one of a pet food manufacturer’s most fundamental and specialized pieces of equipment. When Augury’s AI detected a motor fault indicating possible rotor bar damage on this customer’s hammer mill, the Augury vibration analyst downgraded the machine’s health status to Alarm and advised the onsite team to replace the motor as soon as possible to prevent damage to the machine. It’s extremely difficult to assess the fault severity and remaining machine life when this type of fault appears and is trending upwards, but according to vibration standards, a maintenance team should immediately prepare to replace the motor.

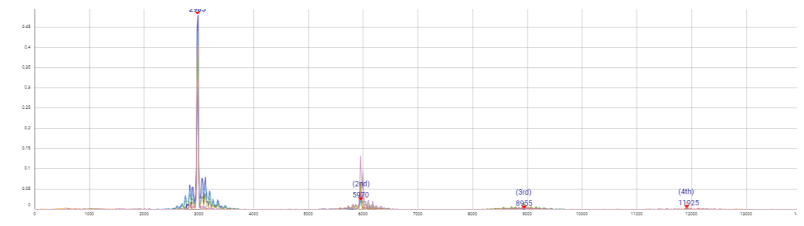

Image 2:

Augury’s algorithms analyze over 840 unique feature sets. Shown below are skirts of sidebands that developed around shaft turning speed harmonics, a textbook indication of possible rotor bar damage.

The customer faced multiple challenges to obtain the needed part, including restrictions on motor efficiency and supply chain concerns due to the pandemic. Because it would require a lead time of several weeks to manage through, the customer took the extra step of verifying Augury’s findings before ordering the part, which an independent testing team confirmed. While waiting for the new motor to arrive, the vibration analyst continued monitoring the machine’s condition and collaborating with the onsite team via the Augury platform, working within their limitations as best they could to avoid total failure and a halt in production.

The onsite team was very responsive, providing feedback to the vibration analyst throughout the process and confirming the success of the repair. After installing the new motor, the onsite team pulled out the rotor of the faulty motor, discovering severe damage, including large burn spots where the connection had failed and gaps where conductive filler had started to deteriorate. As pictured below, it is rare that this type of damage manages to escalate to the point of being so physically evident without the machine failing.

Images 3a and 3b:

Post-repair images showing the damage to the rotor bar. While the image on the right displays typical evidence of moderate damage, the image on the left shows such severe damage that it is surprising the machine was operational.

Without this early detection, the motor would have likely failed catastrophically, potentially halting production for months. Instead, with insights from condition monitoring, the onsite team had adequate time to order the part and prepare for a planned repair before severe secondary damage could occur. Augury helped the customer take the right action at the right time, resulting in zero unplanned downtime.

Want to learn more? Just reach out and contact us!