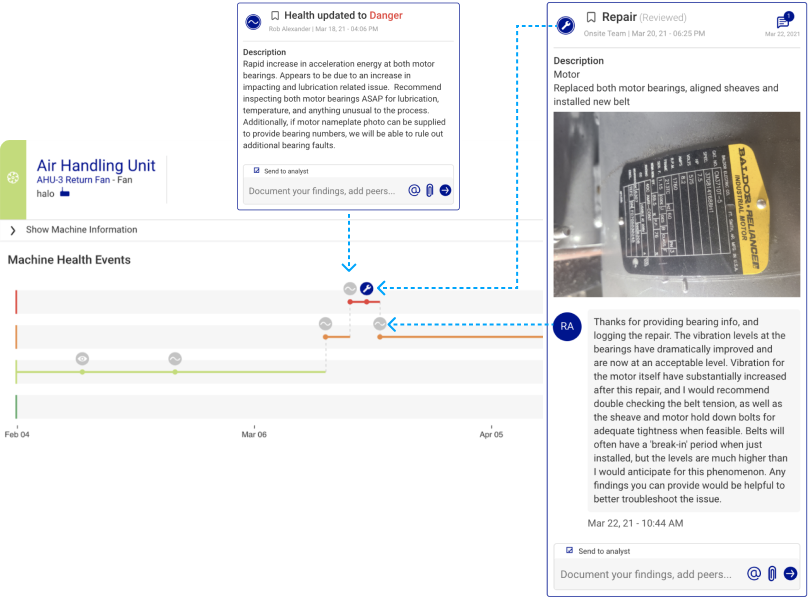

In March of 2021, Augury’s system flagged multiple faults within a critical Air Handling Unit at a leading pharmaceutical company. At first Augury’s system identified rapid impacting and lubrication issues on the machine’s motor bearings, which the site team addressed by replacing the motor’s bearings. While this repair did improve the vibration levels within the motor, Augury’s algorithms also identified mechanical structural looseness and a defective belt developing within the AHU’s fan.

Industry – Pharmaceutical //

Machine – Air Handling Unit //

Fault Type – Impacting, Bearing Lubrication Issues, Mechanical Structural Looseness, Defective Belts //

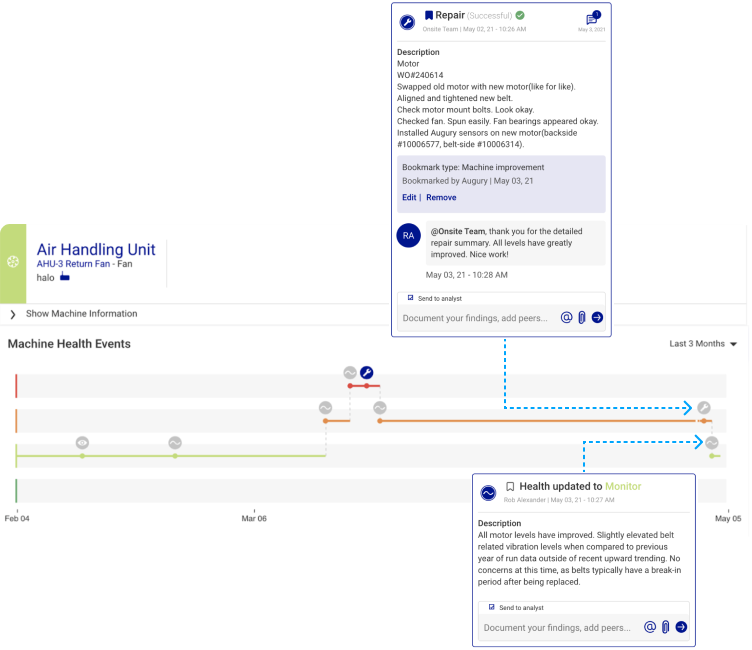

Equipped with detailed fault diagnostics and precise locations, the site team replaced the motor and belts effectively. This second repair was quickly validated by Augury’s system and the machine was upgraded to an improved condition.

Before Augury significant uncertainty existed when it came to machine interventions and repair effectiveness. By leveraging real-time and prescriptive insights, this team was able to take all the necessary steps to avoid downtime, product loss, and potential regulatory violations.