Blood Simple

We ourselves made some headlines over the last month since we announced ‘Augury Acquires Process-Based AI Company Seebo For $100 million’. The industry certainly sat up and listened to headlines such as ‘Roadmap To The Future: Machine Health + Process Health = Production Health’ and ‘The Trillion-Dollar Challenge: Closing The Gap With Production Health’. And yes, we believe we are now very much in a position to deal with the key challenges faced by manufacturers today.

But to give credit where credit is due, we still couldn’t compete with the headline: ‘The Copper Jaws Of Venomous Bloodworms Could Be A Win For Sustainable Manufacturing’.

The article offers a fascinating overview on how “the efficient building process of these unique fangs could improve how composite materials are made.”

Basically, the superlight, super-strong and super-organized fangs are built up around relatively common materials and simple processes.

“What the worm is doing to form its jaws gives us a kind of blueprint for how composite materials can be made more sustainably and less reliant on heavy equipment, for example, mixers, blenders, extruders,” says a researcher. “It’s been a reminder, in an exaggerated way, that simple organisms can harbor really useful technologies.”

Weeding Out Woolliness

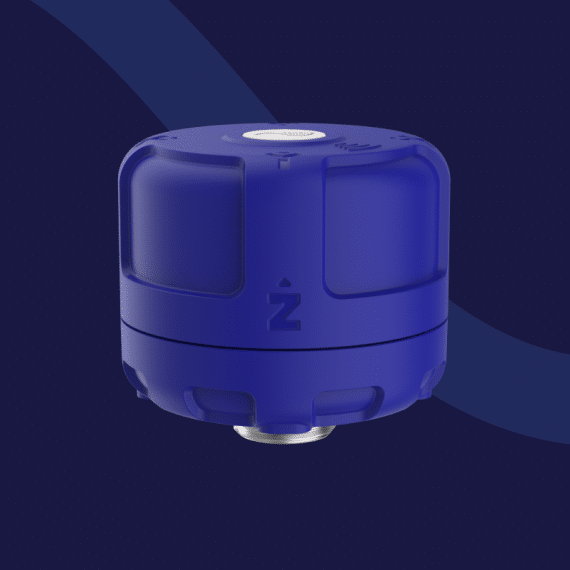

Meanwhile, a whole flurry of other innovations have been announced that indicate that our purpose-driven march towards sustainability is going swimmingly – such as ‘Smart Screws That Can Detect When They’re Loose Could Help Save America’s Bridges’ and ‘Scientists Have Created A Molecule That Can Store Solar Energy For 18 Years’.

But we should be careful about the words we use since their meanings may have become largely meaningless, according to ‘The Woolliest Words In Business: Innovation. Sustainability. Purpose. Yuck’.

“Woolliness is the enemy of accuracy as well as utility. A word like ‘sustainability’ is so fuzzy that it is used to encompass everything from a business that thinks sensibly about the long term to the end of capitalism.”

One way to evaluate if a word is woolly is whether its opposite could possibly be relevant. “Is it even possible to have purposelessness as a goal?”

But yes, it’s possible to go too far when it comes to weeding out woolliness. “Traits like innovativeness or collaborativeness are still qualities for firms to aspire to. And this is not an argument for constant qualification of what is meant: the one way to make ‘purpose’ more annoying is to put the word ‘smart’ in front of it. But it is a plea for managers to use woolly words thoughtfully. They are not going away, but they do not have to suffocate mental activity.”

Let’s Get Concrete

One way to deal with wooliness is to choose related words that might translate more easily into concrete actions. For example, you might get more achievable action points by not talking about a sustainable supply chain, but rather a transparent supply chain.

The increasingly used acronym ESG – environmental, social, governance – also likely evolved from the growing desire to undertake more focused action. But the term remains wooly around the edges: while many are hailing it as the way forward, others such as Elon Musk call it the “devil incarnate”. And certainly, a highly complex system has built up around ESG that works to generate confusion, according to ‘Can Coal Investing Be Environmentally Friendly? A Contrarian Take On ESG‘.

Stop Doing Stupid Stuff

“You might have noticed that everyone says they are ‘sustainable’ these days. True statement. You cannot find any company globally that claims to be unsustainable. Every big company has an ESG function which means they have someone who writes their annual report on how many good deeds they have done and has a statistical heap of actions nicely counted up to prove it,” according to the thought-provoking long-read ‘Will Manufacturing Ever Become Sustainable? No, But At Least Stop Doing Stupid Stuff That Slows The Regenerative Economy Of The Future’.

But “think about it… You produce something. You have factories. You procure metal containers. You ship. You transport via land. You distribute to customers. All of this has a footprint. Denying that is next to impossible. Except we all do. Otherwise, how could we look our children in the eyes?”

The author argues we should be striving for “regenerative manufacturing”. Only with the application of self-replicating autonomous biological systems to build the stuff we need will we become truly sustainable. (All hail venomous bloodworms!)

Meanwhile, we must continue with stopgap measures while amplifying our innovation efforts. “A hundred years from now, I predict that what will have saved us (if we get that far without ecosystem collapse) would be a technological breakthrough that is not yet invented.”

Let’s get to work.