The Automation Pyramid has served us well in representing the different layers of automation in a typical factory. However, some argue the Pyramid is now hindering progress in achieving Industry 4.0. Augury System Sales Engineer Jordan Sprunger believes the Pyramid is far from having lived out its usefulness. “It remains the key to understanding what happens in a factory when introducing innovation.”

Out To Share The Big Picture

My faith in the Automation Pyramid is fully restored – yes, it needs to evolve, but it doesn’t need to disappear. Whether I am talking to colleagues or customers, it’s often a shortcut to mutual understanding.

Take my colleagues, for example. While Augury specializes in helping manufacturers improve their production, we are a deep-tech company with a focus on Machine Health and Process Health. However, modern manufacturers use many technologies both legacy and cutting-edge, and the Pyramid helps us understand the entire scope of our customers’ digital ecosystem.

At the same time, our customers sometimes ask us questions that are antithetical to how our solution is built. I wanted to help bridge these gaps. And in the process, I rediscovered the power of the Automation Pyramid.

The Big Picture

Almost 30 years ago, the ISA95 Enterprise-Control System Integration standards were established to solve an important issue in manufacturing: having a standardized way to communicate between the varying protocols and interfaces of a manufacturing company’s different levels. Successful in its aim, the pyramid-shaped system was soon widely adopted.

Part of the Automation Pyramid’s appeal is its structural clarity, which provides a straightforward view of the different levels involved in automation. From the field level at the bottom to the enterprise level at the top, the model offers a logical framework for understanding how various components interact. And this clarity is invaluable for both seasoned professionals and newcomers to the industry – and particularly when these two groups come together to collaborate.

If It Isn’t Broken, Why Fix It?

However, as we progress deeper into Industry 4.0, it’s assumed that the traditional hierarchal pyramid model will be replaced by a network-structure architecture – a structure more in keeping with the digital IoT world we live in. But, we’re not there yet. The Pyramid still has too many obvious advantages besides just structural clarity and wide-scale use.

For instance, in an era of increasing cybersecurity threats, the segmentation provided by the pyramid model allows for more effective security measures. Each level has its own security protocols, creating multiple layers of protection for critical systems.

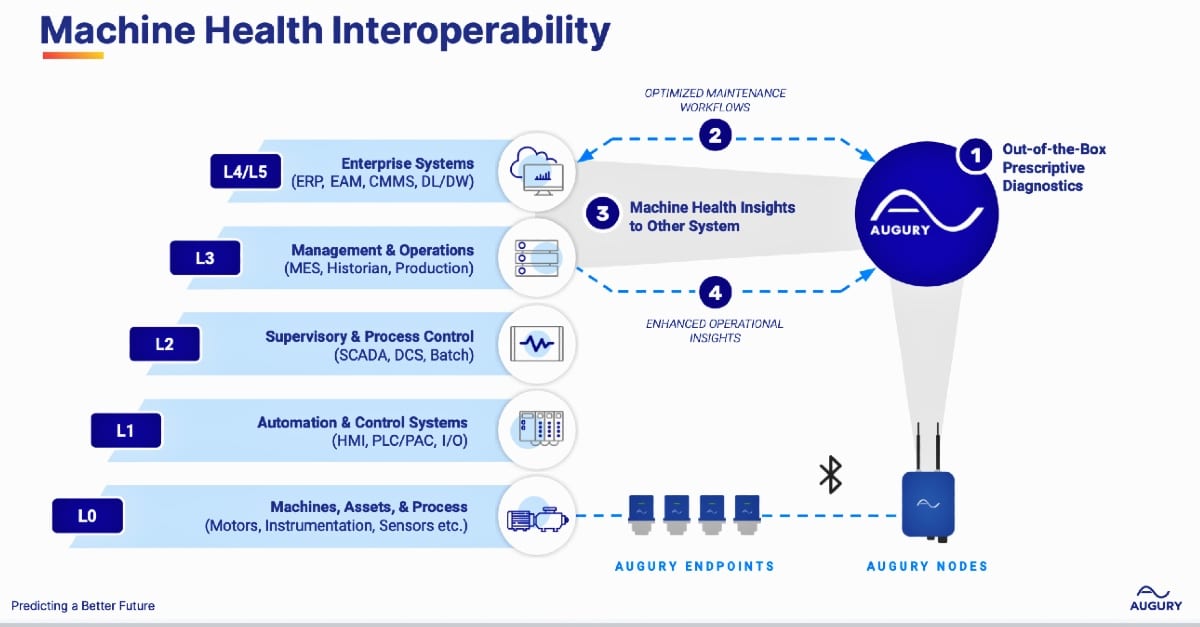

The Art Of Looping In Innovation

At the same time, data no longer flows in a strictly hierarchical manner. For instance, in the case of how Augury’s Machine Health Solution is architected, we actually jump from the base to the tip. Our sensors capture the temperature and vibration data coming from the machines at level zero. But instead of getting bottlenecked by moving through levels 1 to 3 up the pyramid, we go outside the regular path and go straight up to a cloud which, for all intents and purposes, is Level Five – where all the AI magic actually happens.

Meanwhile, our customers are asking for some magic back down at Level Two or Three. So we have to loop that data – along with the actionable insights – back in where the actual action is. This is the level that plant personnel, operators and reliability engineers operate so our insights need to meet them where they work – for instance by triggering automatic work orders when the Machine Health Solution identifies an issue.

This rethinking of the architecture, where all these Level Zero devices can send all their data to a central broker and then to any device or application at any level, is why some industry insiders are saying ‘The Pyramid is dead’ and only slowing us down in achieving Industry 4.0.

As we speak, concepts like edge computing and cloud integration are being seamlessly integrated into the existing framework – enhancing its capabilities without dismantling its core structure.

Tapping Into The Greater Ecosystem – And A Brighter Future

But the fact is the Pyramid’s standardization can facilitate integration of new technologies and can help maintain compatibility between systems from different vendors. And hence, rather than becoming obsolete, the Automation Pyramid is evolving to incorporate new technologies – like what Augury has to offer.

Thankfully, these enhancements promise easier access to data at all levels and that the insights generated can be routed to the right personnel at the right level. This leaves manufacturers free to choose best-in-class solutions for their particular challenges. And you can rest assured that these insights drive value.

In other words, while the underlying technologies and protocols are evolving within the Pyramid, the basic foundational concepts remain. As we speak, concepts like edge computing and cloud integration are being seamlessly integrated into the existing framework – enhancing its capabilities without dismantling its core structure.

This is why many argue for a continued hybrid model that adds an industrial edge computing software layer – one that collects the data from anywhere whether OT or IT. As the underlying technologies may change, the concepts presented by the Automation Pyramid remain relevant to manufacturers operations. Thankfully, these enhancements promise easier access to data at all levels and that the insights generated can be routed to the right personnel at the right level. This leaves manufacturers free to choose best-in-class solutions for their particular challenges. And you can rest assured that these insights drive value.

In other words, it’s about embracing a broader vision.

The Proof Is In The A-Ha’s

However, personally, the best proof for the enduring usefulness of the Automation Pyramid took place last month. I had the luxury of meeting over 100 of my colleagues in person during an offsite at a lakeside camping ground. As I gave my presentation on the Automation Pyramid using the delicious case study of an ice cream factory, I saw many eyes light up. Later, I was approached by many colleagues who thanked me for providing them with the “big picture”.

Mission accomplished.

Case closed.

Want to learn more? Just reach out and contact us!