We are standing in the eye of a perfect storm. To the unassuming bystander, this may seem like just another spring of AI (Artificial Intelligence) following two long winters, or a new attempt at reviving M2M (Machine 2 Machine) technology by slapping a sleek, young, tech-savvy name on it. But this time it’s different.

We are seeing a trifecta of forces pulling our market in different directions – going beyond buzz-words and into real, makes-total-sense ROI territory. These major trends – technology, market needs, and the shift from CAPEX to OPEX – have been lingering around other verticals for decades and have slowly found their way into our market. And when they’ll hit, they’ll hit hard.

From Data to Insights

Neither the Industrial Internet of Things (IIoT) nor Machine Learning are new concepts. The notion of having machines communicate to a central server (previously known as M2M) has fueled the rise of industrial titans like GE, Rockwell Automation and Siemens. What has changed is the exponential decrease in the cost of connectivity and low-power computing. Couple that with easily deployed cloud platforms and you have instant scale. The proliferation of connected sensors is upon us, and it may be trickier to navigate than you imagine.

The onslaught of data that will come from multiple connected sensors is enough to overwhelm even the most experienced facility manager. The key piece of the IIoT is not connecting to the internet, but rather, making sense of all the raw data. Machine learning algorithms have been widely used since the 60’s, but, thanks again to the accessibility of scalable cloud computing, only recently have they outperformed humans in specific tasks. We are now able to train algorithms to beat the best humans in tasks like speech recognition, image recognition or playing strategy games, as long as we have a vast amount of data on which to train them.

The Case for Better Infrastructure

While it may not always be top-of-mind, we all rely on mechanical equipment to live our daily lives. From power plants, to water utilities, office A/C and data centers that store all the pictures we share, machines basically run our lives. But things don’t always go as planned.

Not too long ago, New Orleans was slammed by a massive storm, resulting in eight to ten inches of rain in a matter of hours. People were forced to evacuate from their homes and neighborhoods after homes were damaged due to widespread flooding across the city.

The reason for this crisis rests on sixteen critical pumps. Those particular pumps, which are responsible for pumping water from storm drains to nearby bodies of water, happened to be offline due to planned maintenance and unexpected malfunctions on the day the storm hit. This means that sixteen pumps had the ability to uproot and disrupt the lives of over a million people.

We cannot afford to have the critical equipment that powers our businesses, cities and lives suffer from downtime.

While our nation’s aging infrastructure has been a source of political debate, the solutions aren’t simple ones – replacing all the vital equipment requires tremendous investments while current maintenance paradigms are outdated and inefficient. A move to a more advanced way of thinking, which leverages the advancement in technology to help machines around us be more reliable is required. Enter Predictive Maintenance.

It’s like 1999 All Over Again

The 1999 launch of Salesforce spurred the tech world into a frenzy. The company heralded a paradigm shift in how organizations purchase software – from paying a one-time fee for a typically over-bloated bundle that required frequent and costly updates, to paying an ongoing all-inclusive subscription fee for getting exactly what the customer wants. Over the following decade, Software as a Service (SaaS) would take the world by storm, changing not only the way organizations purchase software, but also how they operate and plan their budget.

IT managers loved SaaS – it took away the overhead of tracking and managing installations and updates of disparate systems, as well as provided a predictable way of projecting expenses. Gone were the days of annual spikes in expenses for an update or switching vendors.

We are currently experiencing the same in the industrial market as well. This shift will enable our industry to deal with its aging infrastructure without the upfront investment that has historically prevented us from reaping the benefits of advanced mechanical diagnostic technology.

The Need for Continuous Diagnostics

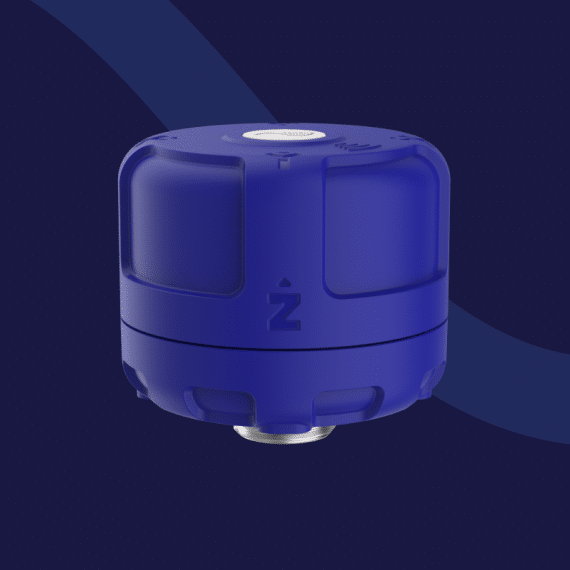

Today we are excited to announce the launch of our newest product – Augury Halo. Halo is the first viable solution for deploying continuous diagnostics at scale. Our sensors wrap your equipment with an invisible field that constantly listens and learns, so you can sleep better at night.

Based on an ever-growing Malfunction Dictionary that includes tens of thousands of machines, and working with over a dozen Fortune 500 companies, our algorithms have been trained to identify the first sign of a malfunction and provide the user with highly actionable insights and recommendations for next steps. No expensive training and no upfront investment are needed thanks to our Diagnostics as a Service (DaaS) pricing model, making Predictive Maintenance truly accessible to every facility.

We are standing in the eye of a perfect storm. By pairing internet-age and mobile-age technologies with pay-as-you-go pricing models, we have the solution to help our partners run their machines in a more efficient, reliable manner with less impact on the environment. And by doing so, help the rest of us that rely on machines on a daily basis, to lead healthier, safer lives.

Learn more about how Augury continues to lead with Machine Health solutions.