This global manufacturer produces flavors for the food industry and fragrances used in beauty and well-being products. Deploying Augury in one of its U.S. plants, the company found quick time-to-value when alerted on a Rox 1 fan and motor just days after installation.

Industry—Flavor and Fragrance//

Machine—Rox 1 fan & motor//

Fault Type—Rotating mechanical looseness//

From Baseline to Alarm

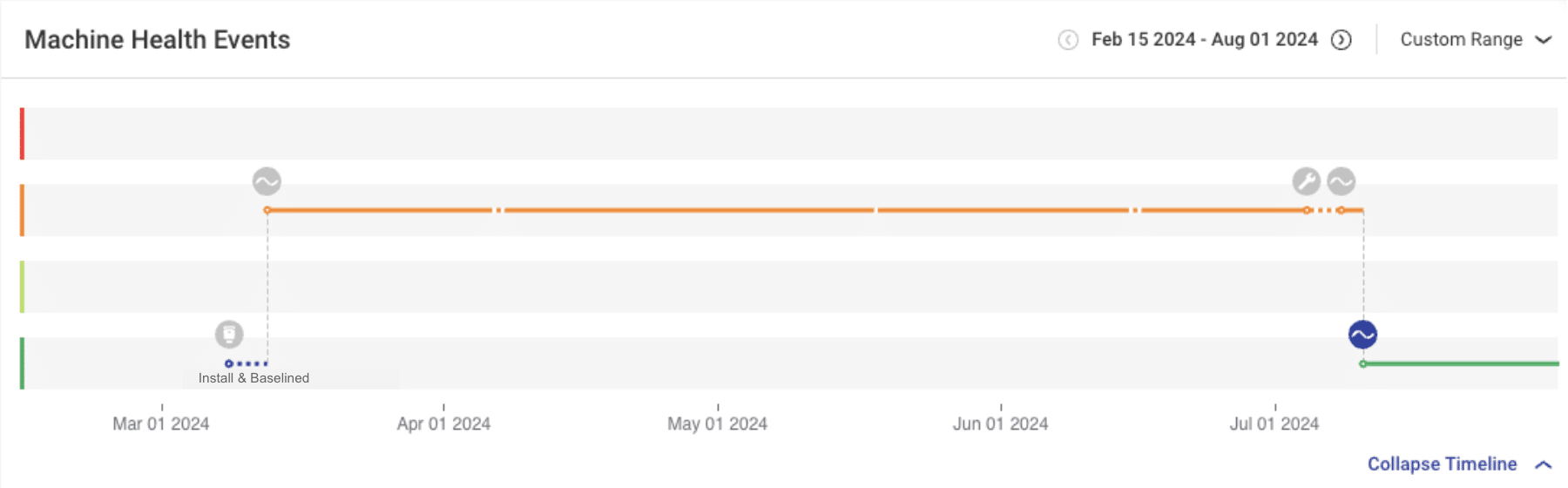

Four days after installing Augury Machine Health sensors on a Rox 1 fan and motor, the machine came out of baseline, immediately indicating “Alarm” status due to signs of rotating mechanical looseness. According to Augury’s analysis, the asset displayed an increasing trend in elevated acceleration amplitudes at the driven fan.

Figure 1: Platform showing machine coming out of baselining activity and into Alarm (March 2024)

The Recommended Fix

Augury advised the plant’s maintenance team to move quickly and attend to the following recommendations:

- Slow rolling the shaft to feel for resistance or roughness

- Performing life and endplay checks with dial indicators to verify bearing/housing clearances

- Ensuring adequate lubrication

The Taste of Victory

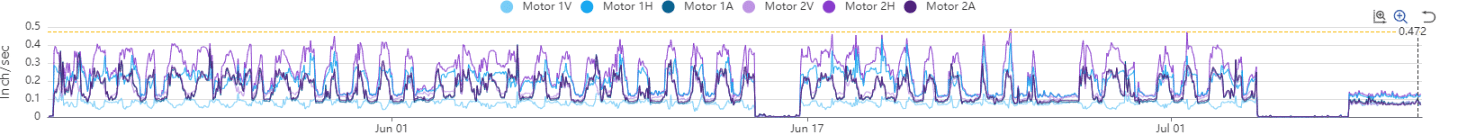

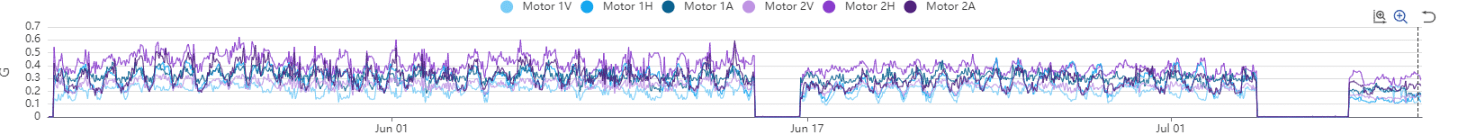

The plant’s team executed a successful repair during scheduled downtime based on Augury’s feedback. Along with new belts, bearings, and laser alignment, they also secured the base of the asset to the concrete foundation below.

Figure 2: Reduction in overall velocity post-repair, July 12 onward

Figure 3: Reduction in high-frequency vibration post-repair, July 12 onward

Plant floor leadership estimated slightly more than $18K in costs avoided – a huge win in saving product, maintaining throughput, reducing waste, and using energy efficiently.

More importantly, a win like this goes deeper than costs avoided. It can also be counted in less tangible ways, like increasing worker safety and morale when repairs are planned in advance rather than operating in reactive, firefighting mode.

Ready to learn how Augury’s Machine Health can help you find stability and predictability on your plant floor? Contact our team for a no-pressure conversation on solutions to your toughest production challenges.