Augury listens to machines. But we also listen to the world. This helps us to better know our place in making it a better place. Here’s a round-up of some of the manufacturing stories from the last month that caught our eye – and why they mattered.

Vaccine Manufacturing is Not Like Making Orange Juice

Is the worst over with the COVID-19 crisis? We hope so. ‘A COVID-19 vaccine life cycle: from DNA to doses’ is an insider view on the daunting challenges related to vaccine production. “I was really excited,” said one facility manager when he heard his plant was going to manufacture COVID-19 vaccine. “I’ve been working in pharmaceutical manufacturing for almost 40 years and I’ve never been on a project like this. I sat down on the couch and a half-hour later I was horrified. My head was spinning.”

“Vaccine manufacturing is an endeavor where an almost infinite combination of things have to work perfectly,” said one expert.

“It’s not like (making) orange juice,” said another.

“It is science with established principles, but sometimes is more idiosyncratic than art,” said a third.

But now tens of millions of doses later, the facility manager and his team have “achieved the impossible”. They cut their production time by half. “I’m really proud that we’ve been able to get to this place,” he says. “When you get everybody pulling in the same direction with the same goal, it’s like magic. Stuff really can happen fast.”

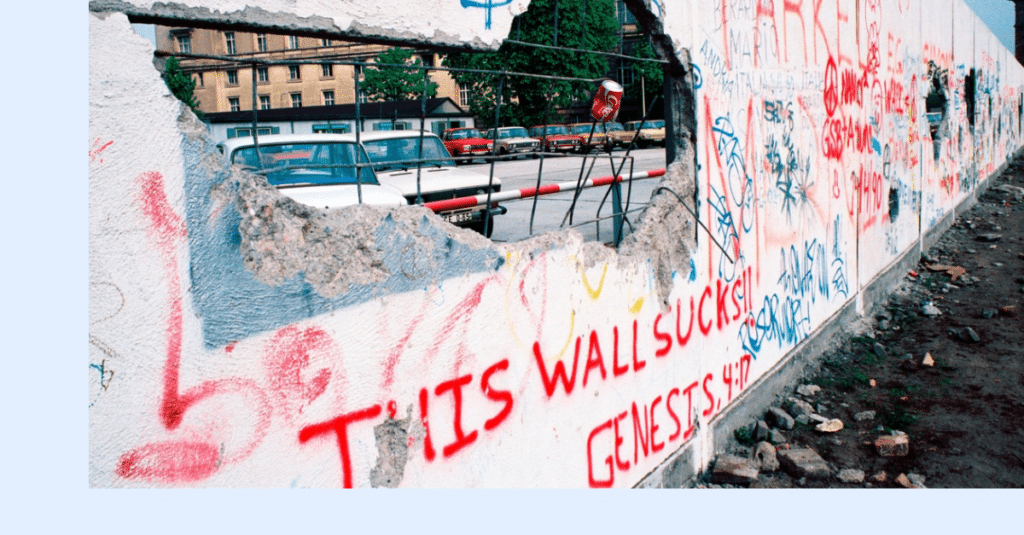

Bumps on the Road

But yes, there can still be bumps on the road. “The newness of some of the technology and gaps in global preparedness have led to bottlenecks,” according to ‘How are Covid vaccines produced and why have there been delays?’.

“The effort to create new vaccines has been amazing, but along the way it’s as if some of the fundamentals have fallen by the wayside – the bread-and-butter stuff that makes scaling up possible,” said one academic. “I really do think people were so focused on the vaccines, they didn’t think further about what needs to come with it to make happen.”

Innovation Matters

‘The 10 most innovative manufacturing companies of 2021’ is a dazzling round-up – even though they forgot to add Augury to slot #1.

“From manufacturing a better vial to carry COVID-19 vaccines in, to devising a biodegradable packaging, to offering on-demand fabrication that reduces waste, these companies are creating a better world by rethinking the ways we create product.”

We were particularly impressed by old dogs, the Ford Motor Co., for pivoting their century-plus of production know-how to pump out tens of millions of masks, face shields and self-designed ventilators.

Size Matters

Meanwhile, there’s a project in India that mirrors the vast ambition of the early days of Ford when they were jumpstarting the automobile manufacturing business. Ola Electric is building the world’s largest two-wheeler factory, according to ‘First Ola Electric vehicle will be launched in June once factory is ready: Bhavish Aggarwal’.

The AI- and automation-driven plant will pump out an eye-watering 10 million EVs a year. “We will have 15% of the world’s production capacity in this single factory and it is going to be fully integrated,” says Aggarwal.

Shall we arrange a Zoom date, Mr Aggarwal?

Turning That Drop in the Bucket into a River of Change

Similar mass ambition should be being applied to providing clean and safe drinking water infrastructures, according to the inspiring ‘How AI and data turn city water management from an art to a science’. In the US alone, a trillion dollars needs to be invested in its ageing water systems – and in the very short-term.

More municipal water managers are embracing innovations similar to what Augury has to offer. “If you use sensors and can detect that potential fracture before it ever occurs, it’s cheaper to fix, you’ve not wasted a lot of water, you’ve not disrupted a city and you’ve taken care of a problem before it actually occurs,” says one.

But many hearts and minds still need to be won over in one of the least disrupted industries on the planet. “We find consistently in our research that people are at the heart of a successful adoption of new technology,” said one expert. “The real value comes from the insights it provides to help them to do their work more effectively.”

We’ll drink to that.

Manufacturing and Toilet Paper in the Limelight. Again

And speaking of flow, all eyes were recently on the Suez Canal blockage – and its staggering costs.

The COVID-19 pandemic had already inspired people to take manufacturing less for granted. (Though it’s somewhat disheartening that it took the fear of running out of toilet paper to turn the term “supply chain” into a household word.)

The blockage worked to further amplify the importance of manufacturing. It also inspired some hilarious memes and quality journalism.

“The Ever Given isn’t stuck anymore, but it will delay tea, dildos, and more,” according to ‘The fallout from the Suez Canal ship is coming to a store near you’. Augury CEO Saar Yoskovitz was quoted in the article saying that not only goods but also raw materials and spare parts were being held up, which could have a negative impact on manufacturing for months to come.

“[Yoskovitz] points to one of the great supply chain incidents of our time — the great toilet paper shortage of 2020 — as a prime example of this: Wood pulp was one of the materials that was severely delayed.”

Let’s hope in the case of wood pulp, the worst is also over.

Interested in reading more news about Augury?